Wind uplift ratings represent one of the most critical yet misunderstood aspects of commercial roof system design. These ratings determine how much wind force your roof can withstand before components begin to lift or separate from the building structure. For commercial property owners in the Texas Panhandle, where wind speeds regularly exceed 60 mph and can reach destructive levels during severe weather events, understanding wind uplift ratings isn't just technical knowledge—it's essential for protecting your investment and ensuring occupant safety.

What Wind Uplift Rating Means and Why It Matters

A wind uplift rating measures the amount of negative pressure (suction force) that a roof system can resist before failure occurs. This rating is expressed in pounds per square foot (psf) and indicates the maximum wind load the roof assembly can handle while maintaining its integrity. The rating applies to the entire roof system, including the membrane, insulation, cover board, fasteners, and their attachment to the structural deck.

Commercial roof systems must meet specific wind uplift requirements based on building codes, which consider factors like building height, location, and exposure category. The National Roofing Contractors Association emphasizes that proper wind uplift resistance is fundamental to roof system performance, as wind-related failures often lead to catastrophic building damage and costly interior losses.

In commercial applications, wind uplift ratings typically range from 60 psf for low-rise buildings in moderate wind zones to over 200 psf for tall structures in high-wind coastal areas. These ratings directly correlate to the building envelope's ability to maintain its protective function during severe weather events.

Key Factors That Determine Wind Uplift Requirements

Several critical factors influence the required wind uplift rating for your commercial roof system. Building height plays a primary role, as wind speeds increase with elevation above ground level. Taller buildings experience higher wind pressures, particularly at roof edges and corners where wind flow creates concentrated uplift forces.

Geographic location and local wind climate significantly impact requirements. The Texas Panhandle's position in Tornado Alley means buildings must withstand not only sustained high winds but also sudden wind direction changes and extreme gusts that can exceed design assumptions. Local building codes reflect these regional challenges by requiring higher uplift ratings than areas with milder wind climates.

Building exposure category also affects uplift calculations. Structures in open areas with minimal wind obstructions face higher uplift pressures than buildings surrounded by other structures or natural windbreaks. The Federal Emergency Management Agency provides detailed guidance on exposure categories and their impact on wind load calculations.

Roof geometry creates additional considerations. Flat commercial roofs experience different uplift patterns than sloped systems, with corner and perimeter zones typically requiring higher resistance ratings than field areas. Understanding these pressure differentials helps ensure proper system design across the entire roof surface.

Testing and Certification Standards

Wind uplift ratings come from standardized testing procedures that simulate real-world wind conditions. FM Global and UL (Underwriters Laboratories) conduct the primary testing protocols used in the roofing industry. These tests subject roof assemblies to gradually increasing negative pressure until failure occurs, establishing the maximum uplift resistance.

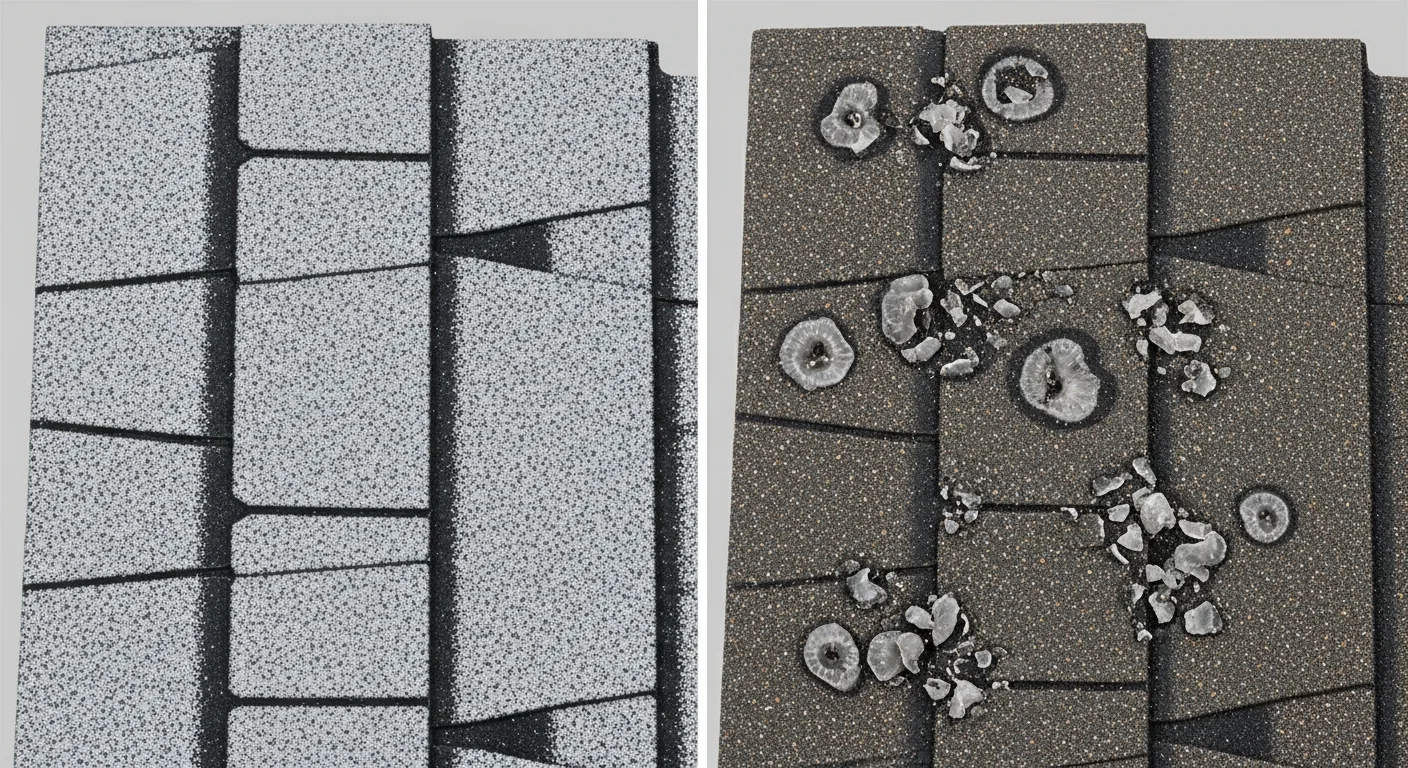

The testing process evaluates complete roof systems, not individual components. This comprehensive approach ensures that the weakest link in the assembly determines the overall rating. Fastener pullout, membrane tearing, and insulation displacement are common failure modes identified during testing.

Commercial Roof System Options and Wind Uplift Performance

Different commercial membrane systems offer varying wind uplift capabilities based on their attachment methods and material properties. Mechanically fastened single-ply systems like TPO and EPDM can achieve substantial uplift ratings when properly designed with adequate fastener density and placement patterns.

Fully adhered membrane systems often provide superior wind uplift resistance because the entire membrane surface bonds to the substrate, distributing uplift forces across the roof area rather than concentrating them at discrete fastener points. These systems typically achieve higher ratings with fewer potential failure points.

Modified bitumen systems offer excellent wind uplift performance through multiple layers and strong adhesive bonds. The redundancy built into these systems provides enhanced security against wind-driven moisture intrusion even if minor lifting occurs at edges or seams.

Ballasted roof systems rely on dead weight to resist uplift forces. While effective in appropriate applications, these systems require careful analysis to ensure adequate ballast weight and proper edge details. Wind scour can reduce ballast effectiveness over time, particularly in high-wind environments.

Critical Design Details for Wind Uplift Resistance

Proper fastener selection and spacing represent fundamental aspects of achieving required wind uplift ratings. Fastener pullout strength must exceed anticipated loads with appropriate safety factors. In the Texas Panhandle's challenging wind environment, this often requires fasteners with enhanced holding power and corrosion resistance.

Edge details demand special attention because roof perimeters experience the highest uplift pressures. Proper edge securement, including appropriate termination methods and enhanced fastening patterns, prevents the progressive failure that can occur when perimeter systems fail first.

Insulation attachment also affects overall system wind uplift performance. Loose-laid insulation can shift or blow away during high winds, compromising both thermal performance and membrane support. Mechanically fastened or adhered insulation provides better wind resistance and maintains roof system integrity.

Wind Uplift Considerations for Storm-Prone Areas

Commercial buildings in the Texas Panhandle face unique wind uplift challenges due to the region's severe weather patterns. Straight-line winds from thunderstorm complexes can exceed hurricane-force levels, while tornado activity creates extreme localized pressures that can challenge even well-designed roof systems.

Temperature extremes compound wind uplift concerns by affecting material properties and system flexibility. Brittle membranes in cold conditions may fail at lower uplift pressures than warm-weather performance would suggest. Conversely, high temperatures can reduce adhesive strength in adhered systems.

The region's hailstorm frequency adds another dimension to wind uplift considerations. Impact-resistant roof systems must maintain their wind uplift performance even after sustaining hail damage. This requirement often influences membrane selection and system design approaches for optimal long-term performance.

Regular severe weather exposure means commercial roof systems must consistently perform at or near their design limits. Unlike areas with occasional high-wind events, Texas Panhandle buildings face repeated stress cycles that can gradually reduce wind uplift resistance through fatigue and weathering.

Insurance and Code Compliance Benefits

Meeting or exceeding required wind uplift ratings provides significant insurance advantages. Many carriers offer premium reductions for buildings with enhanced wind resistance, recognizing the reduced claim probability. Some policies require specific uplift ratings for coverage in high-wind areas.

Building codes increasingly emphasize wind uplift performance as extreme weather events become more frequent and severe. The Insurance Institute for Business & Home Safety promotes building standards that exceed minimum code requirements, providing additional protection and potential insurance benefits.

Proper documentation of wind uplift ratings and installation compliance protects property owners during insurance claims. Detailed installation records and system certification can streamline the claims process and ensure full coverage when wind damage occurs.

When to Consult Professional Commercial Roofing Contractors

Wind uplift rating determination requires specialized knowledge of building codes, testing standards, and local wind conditions. Professional commercial roofing contractors possess the expertise to evaluate your building's specific requirements and recommend appropriate roof systems. Our team understands the unique challenges facing commercial properties in the Texas Panhandle and can help you navigate the complex decisions involved in wind uplift compliance.

Existing roof evaluation presents particular challenges, as aging systems may not meet current wind uplift standards. Professional assessment can identify deficiencies and recommend cost-effective upgrades to improve wind resistance. This proactive approach prevents costly failures and ensures continued building protection.

When considering roof replacement or major repairs, consulting with experienced commercial roofing professionals ensures your new system meets all current wind uplift requirements while providing optimal long-term value. Learn more on our commercial roofing services section to discover how we can help protect your commercial property with properly designed, wind-resistant roof systems that stand up to Texas Panhandle weather conditions.

The Texas Panhandle's unique climate conditions make wind uplift ratings particularly critical for commercial buildings. According to NOAA weather data, the region experiences some of the nation's most severe wind events, with straight-line winds frequently exceeding 70 mph and tornadic activity creating localized wind speeds over 100 mph. These extreme conditions require commercial roof systems to meet or exceed SPRI testing standards for wind uplift resistance, which establish minimum performance thresholds for single-ply membrane systems.

Commercial roof assemblies are tested and rated according to ASTM International standards, specifically ASTM E907 and ASTM D6878, which simulate wind uplift conditions in controlled laboratory environments. These tests measure the pounds per square foot (psf) of negative pressure a roof system can withstand before experiencing membrane separation, fastener pullout, or adhesive failure. For the Texas Panhandle region, commercial buildings typically require wind uplift ratings between 60-90 psf, depending on building height, roof area, and proximity to the building perimeter where wind effects are amplified.

TPO and EPDM membrane systems, such as those manufactured by Carlisle SynTec, achieve high wind uplift ratings through engineered attachment methods including mechanically fastened, fully adhered, and ballasted systems. Mechanically fastened systems often provide the highest uplift resistance, with premium assemblies achieving ratings of 120 psf or higher when properly installed with adequate fastener density and appropriate insulation boards.

The International Building Code (IBC) mandates specific wind uplift requirements based on ultimate design wind speeds, which for most of the Texas Panhandle range from 115-130 mph for Risk Category II buildings. Building owners must ensure their roof systems not only meet these minimum code requirements but also consider the economic benefits of exceeding them, as higher-rated systems often qualify for reduced insurance premiums and demonstrate superior long-term performance in the region's challenging wind environment.

Regular inspection and maintenance of wind uplift systems becomes crucial in high-wind regions like the Texas Panhandle. IBHS research indicates that even minor compromises in membrane integrity or fastener security can dramatically reduce a roof system's wind uplift capacity, making proactive maintenance essential for maintaining the original design ratings throughout the roof's service life.