Texas experiences some of the most severe wind conditions in the United States, with flat commercial roofs bearing the brunt of these powerful forces. Wind uplift failures represent one of the most catastrophic and costly roofing problems facing property owners across the Lone Star State, particularly in areas like Amarillo where high plains winds can exceed 70 mph during severe weather events.

Understanding Wind Uplift Forces on Flat Roofs

Wind uplift occurs when air pressure differences create a vacuum effect above a roof surface, literally attempting to pull the roofing system away from the building structure. Unlike sloped roofs that can deflect wind forces, flat commercial roofing systems present a horizontal surface that acts like an airplane wing, creating lift as wind flows over and around the building.

The physics behind wind uplift are straightforward but devastating. As wind hits a building, it accelerates over the roof surface, creating lower air pressure above the roof than below it. This pressure differential generates upward forces that can range from 20 to over 150 pounds per square foot, depending on wind speed and building height. When these forces exceed the roof system's resistance capacity, catastrophic failure occurs.

Why Flat Roofs Are Particularly Vulnerable

Several factors make flat roofs significantly more susceptible to wind uplift damage than their sloped counterparts. The aerodynamic profile of a flat roof creates maximum lift potential, especially at building edges and corners where wind forces can be amplified by 200-300%. Additionally, the attachment methods used in flat roofing systems often rely on adhesives, ballast, or mechanical fasteners that may not provide adequate uplift resistance.

The National Roofing Contractors Association (NRCA) emphasizes that flat roofs experience more uniform pressure distribution across their entire surface, making them prone to "ballooning" or progressive failure that can strip away large sections of roofing membrane in a single wind event.

Texas Wind Patterns and Their Impact on Commercial Buildings

Texas geography creates unique wind challenges that make the state particularly hazardous for flat roof installations. The combination of Gulf Coast moisture, Rocky Mountain elevation changes, and vast open plains generates complex wind patterns including microbursts, derechos, and sustained high-wind events that can persist for hours.

In the Texas Panhandle, where Amarillo is located, chinook winds can create sudden pressure changes that stress roofing systems beyond their design limits. These warm, dry winds descending from higher elevations can reach hurricane-force speeds with little warning, making wind damage prevention and rapid response critical for commercial property protection.

Seasonal Wind Variations and Risk Factors

Spring months bring the highest risk for severe wind events in Texas, with March through May seeing peak thunderstorm activity that generates damaging straight-line winds and tornadoes. However, winter months can produce equally destructive wind conditions through arctic fronts and pressure gradient winds that may not trigger the same level of preparedness as spring storm season.

According to Department of Energy research, buildings in high-wind zones like much of Texas should be designed to withstand wind speeds of at least 90 mph, with enhanced requirements for critical facilities and high-rise structures where wind amplification effects are more pronounced.

Common Flat Roof Wind Uplift Failure Points

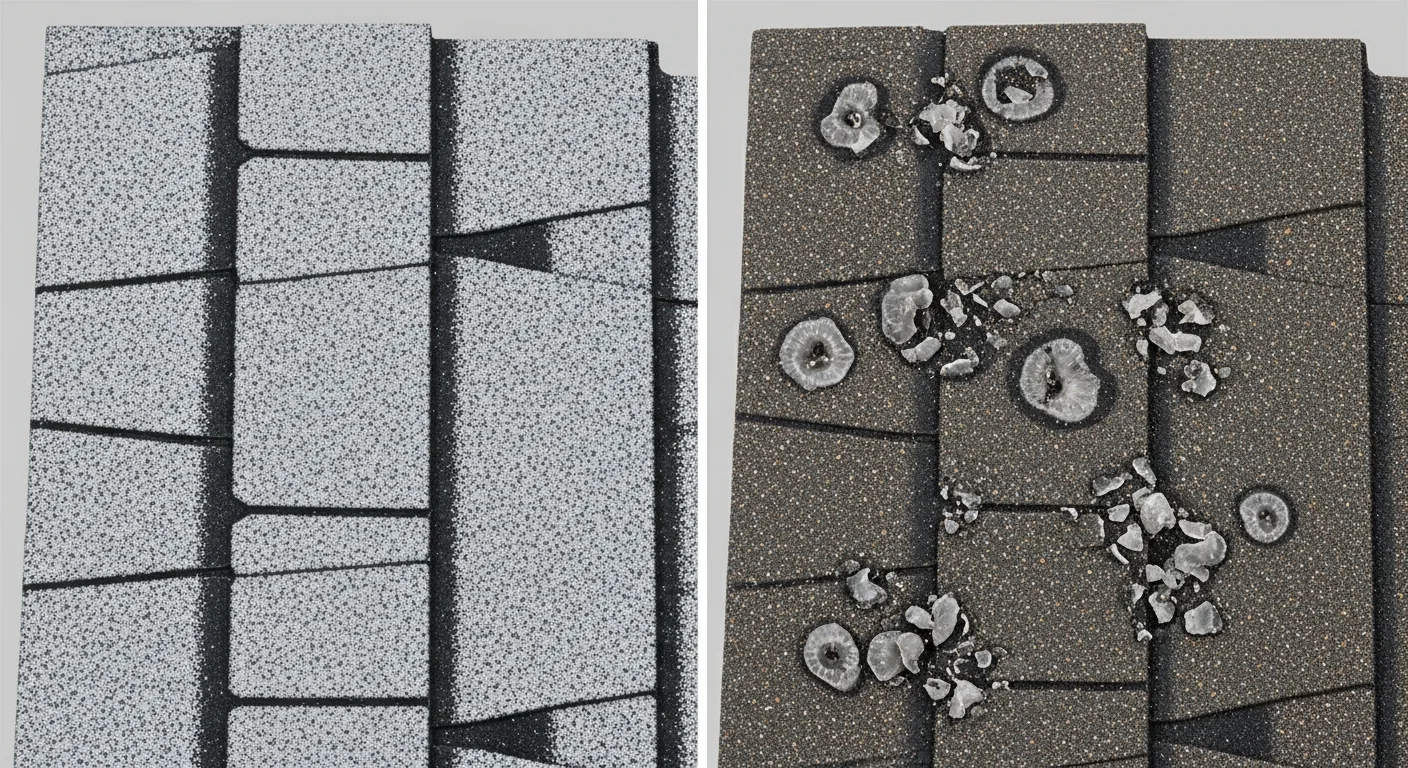

Understanding where flat roofs typically fail during wind events is crucial for both prevention and rapid response. The most vulnerable areas include perimeter edges, corners, roof penetrations, and any location where the roofing membrane attachment is compromised or inadequate.

Edge details represent the highest risk zone, as wind forces concentrate at building perimeters where uplift pressures can be three times higher than in central roof areas. Inadequate edge securement, deteriorated sealants, or insufficient membrane attachment can create entry points where wind gets underneath the roofing system and causes progressive peeling failure.

Penetration and Equipment Vulnerabilities

Roof-mounted equipment, vents, and other penetrations create additional failure points during high-wind events. These elements can act as sails, catching wind and transferring destructive forces directly to the roof membrane and structural deck. Poor flashing details around penetrations often allow water infiltration that weakens adhesive bonds and mechanical attachments over time.

Immediate repair attention to any penetration damage is essential, as even small breaches can rapidly expand during subsequent wind events, leading to total roof system failure and significant interior damage.

Building Codes and Wind Uplift Standards in Texas

Texas building codes have evolved significantly in response to repeated wind damage events, with current requirements based on International Building Code provisions that mandate specific wind uplift resistance ratings for different roof zones and building types. These standards recognize that flat roofs require enhanced attachment methods and materials to resist the unique forces they experience.

The Federal Emergency Management Agency (FEMA) provides guidance on wind-resistant construction that emphasizes the importance of continuous load paths from roof surface to foundation, ensuring that wind forces can be safely transferred through the building structure rather than causing localized failures.

Insurance and Liability Considerations

Property insurance policies increasingly include specific provisions for wind damage claims, with many insurers requiring compliance with enhanced wind standards to maintain full coverage. Failure to meet current building codes or industry standards for wind uplift resistance can result in claim denials or reduced settlements following storm damage.

The Insurance Institute for Business & Home Safety (IBHS) conducts extensive testing on roofing systems and provides certification programs that help property owners demonstrate compliance with best practices for wind resistance, potentially qualifying for insurance premium reductions.

Prevention and Mitigation Strategies

Preventing wind uplift failures requires a comprehensive approach that addresses design, materials, installation, and maintenance. Modern flat roofing systems must incorporate adequate attachment methods, appropriate materials for local wind conditions, and regular inspection protocols to identify potential vulnerabilities before they become catastrophic failures.

Mechanical attachment systems generally provide superior wind uplift resistance compared to adhesive-only applications, particularly when combined with proper fastener spacing and penetration depths. Manufacturers like GAF and Owens Corning provide detailed technical specifications for achieving required uplift ratings in various wind zones.

Regular Maintenance and Inspection Programs

Proactive maintenance represents the most cost-effective strategy for preventing wind uplift failures. Regular inspections should focus on edge details, penetration flashing, membrane condition, and any signs of prior wind damage that may have compromised system integrity. Semi-annual inspections, particularly before and after severe weather seasons, can identify problems while they remain manageable and affordable to address.

Emergency preparedness planning should include provisions for rapid post-storm inspections and temporary repairs to prevent water intrusion if wind damage occurs. Having established relationships with qualified commercial roofing contractors ensures faster response times when emergency repairs are needed to prevent additional damage.

Technology and Innovation in Wind-Resistant Roofing

Advances in roofing materials and installation techniques continue to improve wind uplift resistance for flat roof systems. Modified bitumen membranes, EPDM systems, and thermoplastic materials each offer distinct advantages for high-wind applications when properly specified and installed according to manufacturer requirements.

Companies like Firestone Building Products have developed specialized attachment systems and membrane formulations specifically designed for extreme wind conditions, providing property owners with enhanced protection options that exceed basic code requirements.

Future developments in smart roofing systems may include embedded sensors that monitor wind loads and membrane stress in real-time, providing early warning of potential failures and enabling preventive intervention before catastrophic damage occurs. These technologies promise to transform how commercial properties manage wind-related risks in high-exposure areas like Texas.

The Texas Panhandle's unique climate presents exceptional challenges for flat roof systems. According to NOAA weather data, the Amarillo region experiences sustained winds exceeding 25 mph for over 100 days per year, with severe thunderstorm events producing gusts that can reach 90+ mph. These conditions, combined with dramatic temperature fluctuations that can span 60 degrees within 24 hours, create the perfect storm for wind uplift failures.

Commercial membrane systems face particular vulnerabilities in this environment. Single-ply membranes like TPO and EPDM, while popular for their cost-effectiveness, require proper attachment methods to resist uplift forces. SPRI (Single Ply Roofing Industry) standards specify that commercial roofs in high-wind zones like the Texas Panhandle must achieve uplift ratings of FM-90 or higher, meaning they can withstand uplift pressures of at least 90 pounds per square foot.

The International Code Council's building standards classify most of the Texas Panhandle as Wind Zone II, requiring enhanced attachment schedules for roof membranes. This typically means increasing fastener density from standard 12-inch spacing to 6-inch spacing along perimeters and corners, where uplift forces concentrate. Additionally, fully adhered systems using manufacturers like Carlisle SynTec's Sure-Weld TPO often outperform mechanically attached systems in extreme wind conditions.

Recent research from the National Wind Institute at Texas Tech has identified that buildings over 30 feet in height experience wind speed amplification factors of 1.3 to 1.5 times surface wind speeds. This means that during a 70 mph windstorm, a three-story commercial building could experience effective wind speeds exceeding 100 mph at the roof level. Property owners must factor these amplification effects when specifying uplift-resistant roofing systems.

The Insurance Institute for Business & Home Safety (IBHS) recommends that flat roofs in high-wind regions incorporate enhanced edge details, increased insulation attachment, and regular maintenance programs to identify potential weak points before they fail catastrophically. Their FORTIFIED Commercial standards provide a roadmap for achieving superior wind resistance that can significantly reduce insurance premiums and minimize business interruption risks.