Your flat roof has served you well, but now you're facing a critical decision that could impact your property's value, safety, and your budget for years to come. In the harsh Texas Panhandle climate, where extreme temperature swings, relentless UV exposure, and sudden hailstorms put extraordinary stress on building envelopes, the line between repair and replacement can mean the difference between a smart investment and costly emergency repairs down the road.

When moisture intrusion begins compromising your roof's thermal performance and structural integrity, every day of delay increases the potential for catastrophic damage to your interior systems, inventory, and operations. The question isn't just about immediate costs—it's about making a strategic decision that protects your investment while minimizing long-term lifecycle costs.

When Flat Roof Issues Require Professional Assessment

Several critical indicators signal when your flat roof has moved beyond simple maintenance into replacement territory. Multiple membrane failures across different sections indicate systemic breakdown of your roofing system's integrity. When you're experiencing recurring leaks despite previous repairs, this suggests the underlying substrate or insulation has been compromised by chronic moisture intrusion.

In the Texas Panhandle's extreme climate, widespread membrane shrinkage and cracking often develops after 15-20 years of thermal cycling. These temperature fluctuations—sometimes exceeding 60-degree daily swings—cause constant expansion and contraction that eventually breaks down membrane seams and flashings. When you notice ponding water that doesn't drain within 48 hours after precipitation, this indicates structural settling or inadequate slope that requires comprehensive reconstruction.

Energy efficiency decline represents another crucial factor. If your HVAC costs have steadily increased despite normal usage patterns, deteriorated insulation and compromised thermal reflectivity may be forcing your systems to work harder. According to the Department of Energy, a failing roof can increase cooling costs by 15-25% in hot climates like ours.

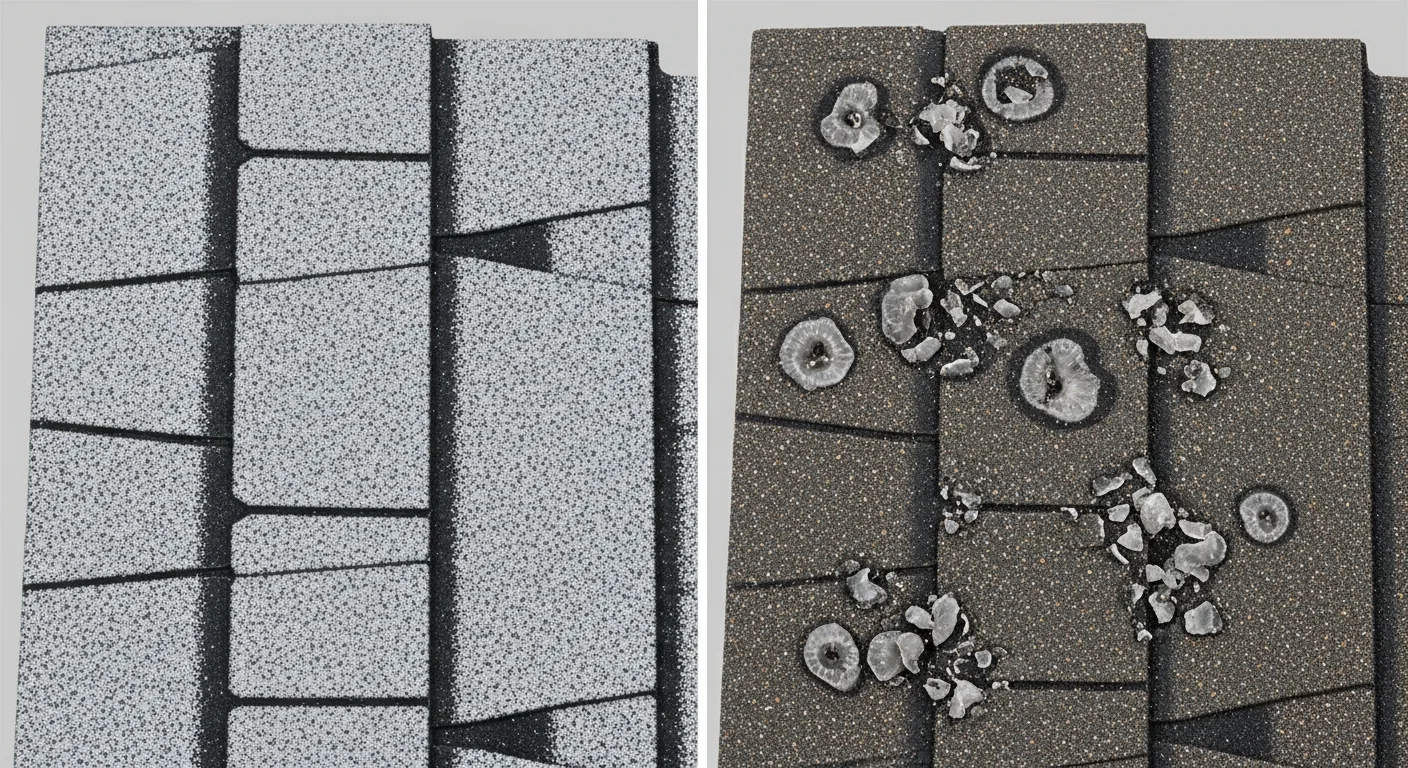

Professional roof inspection becomes essential when you observe granule loss on modified bitumen systems, extensive blistering on built-up roofs, or visible deterioration of TPO or EPDM membrane surfaces. These symptoms often indicate that your roof's protective capabilities have been compromised to the point where repairs become temporary fixes rather than long-term solutions.

Key Decision Factors: Repair vs. Replacement Analysis

The financial mathematics of repair versus replacement depends on several critical factors that experienced contractors evaluate systematically. Age and expected remaining service life represent the primary consideration. If your roof has reached 75% of its expected lifespan while requiring significant repairs, replacement typically offers better return on investment.

Cost analysis should examine both immediate expenses and projected future maintenance. When repair costs exceed 25-30% of replacement value, or when you've invested more than 50% of replacement cost in repairs over the past five years, replacement becomes the fiscally responsible choice. This calculation becomes more compelling when you factor in the warranty protection and energy savings that new roofing systems provide.

Insurance considerations often tip the scale toward replacement. Many insurers provide more favorable coverage for properties with newer roofing systems, while older roofs may face coverage limitations or higher deductibles. Additionally, building code compliance issues may require system upgrades that make partial repairs impractical.

Timeline pressures in our climate demand urgent attention. Texas Panhandle weather patterns can shift rapidly from drought conditions to severe storms, making temporary repairs vulnerable to sudden failure. Peak construction seasons and material availability can also impact project scheduling, making early decision-making crucial for optimal outcomes.

The scope of necessary work provides another decision point. If repairs require extensive removal of existing materials, structural modifications, or insulation replacement, the labor and disposal costs often approach replacement levels while providing significantly shorter service life.

Material and System Recommendations for Texas Panhandle Conditions

Selecting the right replacement system requires understanding how different materials perform under our region's unique environmental stresses. TPO (Thermoplastic Polyolefin) membranes excel in high-temperature environments, offering superior thermal reflectivity and heat-welded seams that resist wind uplift pressures common in our area. These systems typically provide 20-25 year service life with proper installation and maintenance.

Modified bitumen systems remain popular for their proven durability against thermal cycling and hail impact. When reinforced with polyester mats and protected by ceramic granules, these systems resist Texas weather extremes while providing excellent waterproofing performance. The National Roofing Contractors Association recommends specific installation techniques for high-wind regions like ours.

For commercial applications requiring maximum longevity, spray polyurethane foam systems provide exceptional thermal performance and seamless application that eliminates leak-prone membrane seams. These systems offer outstanding R-value improvement while conforming to irregular roof geometries and penetrations.

Cool roof technology integration becomes increasingly important as energy codes evolve. Systems with high solar reflectance and thermal emittance can reduce surface temperatures by 50-80°F compared to conventional dark-colored roofs, significantly impacting cooling costs and extending system life through reduced thermal stress.

Insulation upgrades during replacement provide opportunity for substantial energy improvements. Polyisocyanurate and XPS foam boards offer excellent thermal performance and moisture resistance, while proper vapor barrier installation prevents condensation issues that plague many existing systems.

What to Expect During the Replacement Process

Pre-construction planning begins with comprehensive structural assessment and core sampling to determine existing conditions and substrate integrity. This evaluation identifies any decking repairs, drainage improvements, or structural modifications required before new system installation.

Material procurement and delivery scheduling require careful coordination, particularly during peak construction seasons. Quality contractors maintain relationships with multiple suppliers to ensure material availability and competitive pricing, while weather monitoring helps optimize installation timing.

Tear-off and disposal procedures must comply with environmental regulations while minimizing disruption to your operations. Professional contractors implement containment protocols to prevent debris infiltration and coordinate waste removal efficiently. Complete removal allows thorough inspection of structural components and proper preparation for new system installation.

Installation typically proceeds in phases to maintain building protection throughout the process. Quality control measures include adhesion testing, seam integrity verification, and thermal imaging inspection to ensure complete system performance. Experienced installers understand how Texas weather conditions affect material handling and application procedures.

Final inspection and documentation provide essential warranty protection and building code compliance verification. Professional contractors provide detailed warranty information, maintenance recommendations, and emergency contact procedures to protect your investment long-term.

Why Choosing the Right Contractor Makes the Difference

Contractor expertise directly impacts system performance and longevity. Experienced Texas Panhandle roofers understand local climate challenges, building code requirements, and insurance compliance issues that affect project success. They maintain manufacturer certifications that provide enhanced warranty protection and access to latest installation techniques.

Proper licensing and insurance coverage protect your property and financial interests throughout the project. Established contractors carry comprehensive general liability and workers' compensation insurance, while bonding provides additional security for large projects. Verify contractor credentials through state licensing boards and Better Business Bureau ratings.

Material sourcing and supplier relationships influence both project cost and quality outcomes. Reputable contractors maintain partnerships with leading manufacturers, ensuring authentic materials and factory support for warranty claims. They also provide competitive pricing through established purchasing agreements and volume discounts.

Local knowledge proves invaluable for navigating permit requirements, inspection procedures, and weather-related scheduling challenges. Contractors familiar with local building officials and inspection processes ensure smooth project completion and proper documentation for warranty protection.

Emergency response capabilities become crucial when unexpected weather threatens exposed roof areas during replacement. Established local contractors maintain equipment and personnel resources to provide immediate protection and continue work as conditions permit.

Don't let uncertainty about repair versus replacement decisions compromise your property's protection and your budget. CRS Roofing & Construction brings over two decades of Texas Panhandle experience to every flat roof evaluation, providing honest assessments that prioritize your long-term interests over short-term profits. Our certified technicians use advanced diagnostic tools and comprehensive cost analysis to help you make informed decisions backed by manufacturer warranties and our commitment to quality.

Contact CRS Roofing & Construction today for a professional flat roof assessment that examines all critical factors affecting your replacement decision. We'll provide detailed cost comparisons, timeline projections, and material recommendations tailored specifically to your property's needs and our region's challenging climate conditions. Your roof replacement investment deserves expert guidance—call now to schedule your consultation and protect your property with confidence.

The Texas Panhandle's unique climate presents specific challenges that accelerate flat roof deterioration. According to the National Severe Storms Laboratory, this region experiences some of the most intense hailstorms in the United States, with hail sizes frequently exceeding 2 inches in diameter. When combined with wind speeds that can reach over 70 mph during severe weather events, these conditions create a perfect storm for membrane punctures, seam failures, and substrate damage that may not be immediately visible.

Understanding the specific performance requirements for flat roofing systems in this climate is crucial for making informed replacement decisions. The Single Ply Roofing Industry (SPRI) standards indicate that TPO and EPDM membranes should maintain their flexibility and UV resistance for at least 20 years under normal conditions. However, in the Texas Panhandle's extreme environment, thermal cycling between winter lows of -10°F and summer highs exceeding 110°F can reduce this lifespan by 25-30%. When your roof shows signs of widespread membrane brittleness, chalking, or dimensional instability across multiple areas, replacement becomes the most cost-effective long-term solution.

Modern flat roofing systems from manufacturers like Carlisle SynTec now incorporate advanced polymer technologies specifically designed to withstand extreme weather conditions. Their TPO membranes feature enhanced puncture resistance and thermal stability that significantly outperform older installations. When evaluating replacement options, consider systems that meet or exceed the ENERGY STAR cool roof requirements for reflectivity and emissivity, which can reduce cooling costs by 10-15% in our intense summer heat.

Safety considerations also play a critical role in the repair versus replacement decision. OSHA regulations require specific fall protection measures when workers are performing roof maintenance or repairs. Repeatedly accessing a deteriorating roof for patch repairs not only increases safety risks but often costs more over time than a single replacement project. Additionally, building codes may require upgrades to insulation levels and drainage systems during major roof work, making replacement the more practical choice when multiple repairs are needed.

The economic analysis becomes clearer when you consider that a professionally installed flat roof replacement typically carries warranties of 15-25 years, while repairs may only provide 1-3 years of reliable service. In the harsh Texas Panhandle environment, this extended protection period, combined with improved energy efficiency and reduced maintenance costs, often justifies the initial investment in replacement over continued repairs.