Your roof endures relentless punishment from the Texas Panhandle's extreme weather—from scorching 100°F summers to destructive hail storms that can devastate an entire building envelope in minutes. Without regular professional inspections, minor issues like loose membrane seams or compromised thermal reflectivity can escalate into catastrophic moisture intrusion, costing thousands in emergency repairs. In Amarillo's volatile climate, the difference between a $500 maintenance fix and a $50,000 roof replacement often comes down to early detection through comprehensive professional assessment.

When Professional Roof Inspection Requires Immediate Attention

The Texas Panhandle's severe weather patterns demand proactive inspection protocols that go far beyond visual assessments. Professional roof inspections become critical after hail events exceeding 1-inch diameter, wind storms with sustained speeds over 60 mph, or when your building experiences temperature swings exceeding 40 degrees within 24 hours—conditions that stress roofing systems beyond normal tolerance levels.

According to the Insurance Institute for Business & Home Safety, undetected roof damage increases repair costs by an average of 300% when left unaddressed for more than six months. In Amarillo's climate, this timeline compresses significantly due to accelerated weathering from UV exposure and thermal cycling.

Professional inspection becomes non-negotiable when you notice interior water stains, increasing energy costs indicating compromised R-value performance, or granule accumulation in gutters signaling membrane deterioration. These symptoms often indicate underlying structural compromise that requires immediate professional evaluation to prevent catastrophic failure during the next severe weather event.

Key Decision Factors: Repair vs. Replacement Analysis

Professional roof inspections provide critical data for lifecycle cost analysis, helping property owners make informed decisions between targeted repairs and complete system replacement. In the Texas Panhandle, this decision hinges on several quantifiable factors that experienced contractors evaluate systematically.

Age and remaining service life represent the primary consideration. Asphalt shingle systems approaching 15-20 years in Amarillo's intense UV environment typically require replacement rather than repair, as the accelerated aging from thermal cycling compromises overall system integrity. Modified bitumen and single-ply membrane systems may warrant repair if damage affects less than 25% of the total roof area and the substrate remains structurally sound.

Energy efficiency considerations often justify replacement even when repairs remain technically viable. Modern roofing systems with enhanced thermal reflectivity can reduce cooling costs by 20-30% compared to older installations, creating compelling ROI scenarios that professional inspectors quantify during assessment. For our commercial roofing services page, we detail how energy-efficient systems provide measurable returns that often finance the upgrade through utility savings alone.

Insurance implications significantly impact repair versus replacement decisions. Most carriers require professional documentation of storm damage within specific timeframes, making prompt inspection essential for claim viability. Professional inspectors understand insurance requirements and provide documentation that supports optimal claim outcomes while ensuring compliance with local building codes.

Material and System Recommendations Based on Inspection Findings

Professional roof inspections reveal specific performance characteristics that guide material selection for repairs or replacements optimized for Texas Panhandle conditions. Experienced inspectors evaluate wind uplift resistance, impact ratings, and thermal performance to recommend systems that provide maximum longevity in our challenging climate.

For residential applications, impact-resistant shingles rated Class 4 by UL 2218 standards provide essential protection against frequent hail events while offering insurance premium reductions up to 30%. Professional inspectors assess existing attachment patterns and decking conditions to determine compatibility with upgraded materials that enhance wind uplift resistance to meet or exceed current building codes.

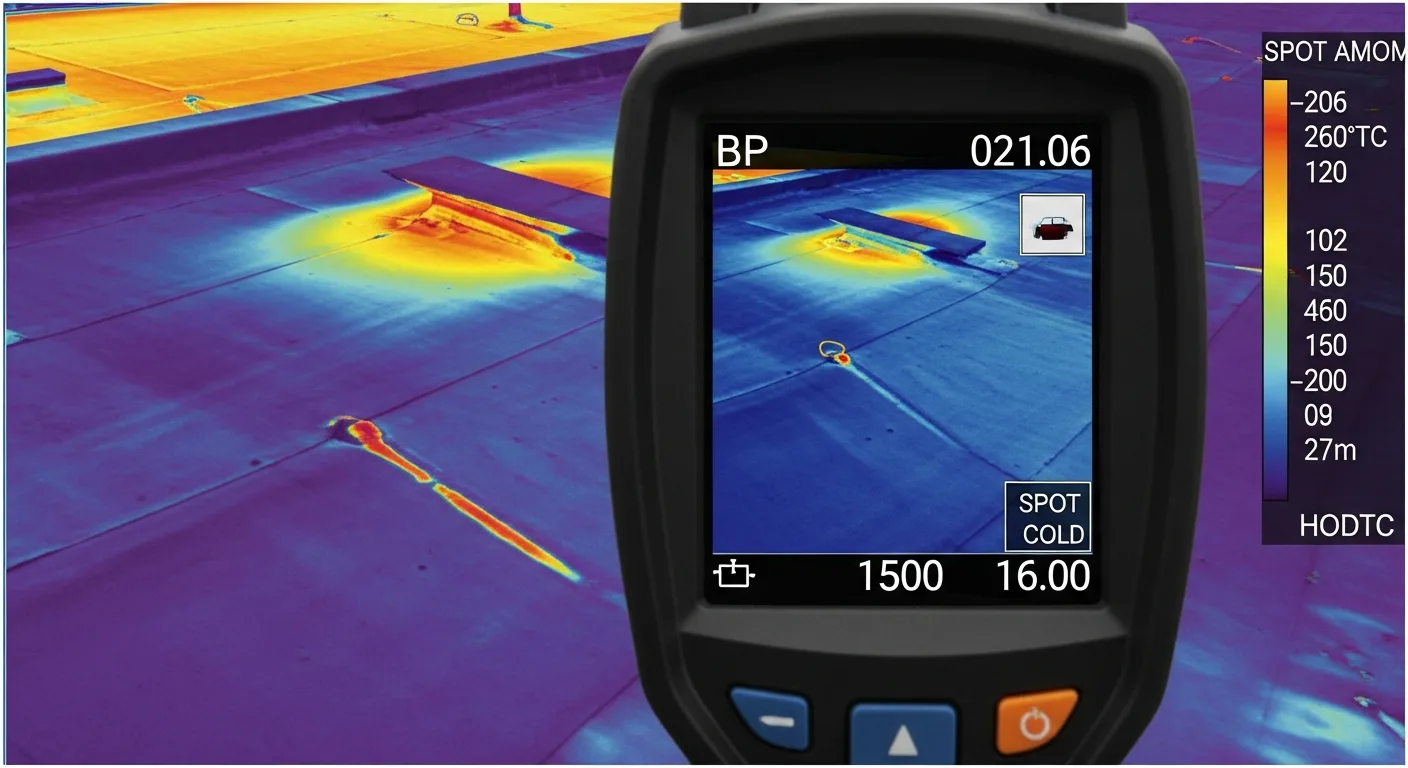

Commercial membrane systems require specialized evaluation of seam integrity, drainage adequacy, and thermal movement accommodation. Professional inspectors utilize infrared thermography and core sampling to identify moisture intrusion patterns invisible to visual inspection, providing data essential for system-specific repair protocols or replacement recommendations.

Material recommendations incorporate ENERGY STAR certified products that provide measurable energy savings while meeting local code requirements for solar reflectance and thermal emittance. These specifications become particularly important for commercial applications where energy costs represent significant operational expenses.

What to Expect During the Professional Inspection Process

Comprehensive professional roof inspections follow systematic protocols that ensure thorough evaluation of all building envelope components. Understanding this process helps property owners prepare appropriately and recognize the value professional assessment provides compared to informal visual reviews.

Pre-inspection documentation begins with reviewing building plans, previous inspection reports, and maintenance records to understand system history and identify areas requiring focused attention. Professional inspectors coordinate with property managers to ensure safe access and minimize operational disruption during the evaluation process.

The physical inspection phase utilizes specialized equipment including infrared cameras for moisture detection, core sampling tools for substrate evaluation, and calibrated instruments for measuring membrane thickness and adhesion strength. Inspectors systematically evaluate drainage systems, penetration seals, expansion joints, and edge details where failure commonly initiates.

Safety protocols during inspection include fall protection systems, weather monitoring, and coordination with building operations to prevent accidents or operational interruptions. Professional contractors maintain comprehensive insurance coverage and follow OSHA guidelines that protect both inspection personnel and building occupants throughout the process.

Documentation includes detailed photography, measurements, and material condition assessments that provide baseline data for future comparisons. Professional reports include prioritized recommendations with cost estimates and timeline requirements that enable informed decision-making for maintenance planning and budget allocation.

Advanced Diagnostic Techniques

Modern roof inspection incorporates sophisticated diagnostic tools that reveal problems invisible to conventional assessment methods. Thermal imaging identifies moisture intrusion patterns and insulation deficiencies that compromise energy efficiency, while electronic leak detection pinpoints precise failure locations in membrane systems without destructive investigation.

Core sampling provides definitive analysis of insulation conditions, vapor barrier integrity, and structural deck adequacy—critical information for determining repair feasibility versus replacement requirements. These advanced techniques justify professional inspection costs through precise problem identification that prevents unnecessary repair expenses.

Why Choosing the Right Contractor for Inspection Matters

The quality of professional roof inspection directly correlates with contractor expertise, certification credentials, and local experience with Texas Panhandle weather patterns. Selecting qualified professionals ensures accurate assessment and appropriate recommendations that protect your investment while maximizing insurance claim potential.

Certification and training standards distinguish professional contractors from general maintenance personnel. Look for inspectors certified by the National Roofing Contractors Association (NRCA) or manufacturers like GAF Master Elite or Owens Corning Platinum contractors who maintain ongoing education requirements and proven performance standards.

Local experience becomes crucial for accurate assessment in the Texas Panhandle's unique climate conditions. Contractors familiar with regional weather patterns, building codes, and insurance requirements provide insights that generic inspection services cannot match. This expertise proves invaluable during insurance claim processes where local knowledge impacts settlement outcomes significantly.

Insurance and bonding verification protects property owners from liability during inspection activities while ensuring financial recourse if inspection errors lead to missed problems or inappropriate recommendations. Reputable contractors maintain comprehensive general liability, workers' compensation, and professional indemnity coverage appropriate for their scope of services.

Technology capabilities separate professional inspection services from basic visual assessments. Advanced diagnostic equipment, comprehensive reporting systems, and digital documentation provide value that justifies professional fees through more accurate problem identification and detailed recommendations that guide optimal repair or replacement decisions.

Take Action Now to Protect Your Investment

Don't wait for visible damage to appear—by then, costly moisture intrusion may already be compromising your building's structural integrity. Professional roof inspection provides the critical intelligence needed to maintain your roofing system proactively, maximize insurance coverage, and prevent emergency situations that disrupt operations and drain budgets unexpectedly.

CRS Roofing & Construction's certified inspection team combines decades of Texas Panhandle experience with advanced diagnostic equipment to provide comprehensive assessment and actionable recommendations. Our detailed reports include prioritized maintenance schedules, budget planning guidance, and insurance documentation that protects your interests while extending your roofing system's service life. Contact us today at (806) 553-ROOF to schedule your professional inspection and discover how proactive assessment saves thousands in emergency repair costs while ensuring optimal performance from your roofing investment.

Professional inspectors in the Texas Panhandle utilize specialized equipment calibrated for extreme weather detection, including infrared thermography to identify thermal bridging and moisture intrusion invisible to standard visual assessments. The National Roofing Contractors Association mandates that comprehensive inspections in high-wind zones like Amarillo include fastener pattern verification, membrane bond strength testing, and flashing integrity assessment using industry-standard protocols that exceed basic warranty requirements.

Wind uplift resistance becomes critical when sustained winds exceed 90 mph—a common occurrence during Texas Panhandle thunderstorms. Commercial roofing systems require FM Global wind uplift ratings of 1-90 or higher, while residential installations must meet IRC requirements for 110-mph wind zones. Professional inspectors verify that fastener spacing, insulation attachment, and edge securement meet these stringent standards, as failure rates increase exponentially when installations deviate from manufacturer specifications.

Thermal cycling damage represents a unique challenge in Amarillo's climate, where surface temperatures can fluctuate from 140°F during summer days to below freezing within hours. This extreme cycling causes membrane expansion and contraction rates that stress seam integrity beyond normal parameters. Oak Ridge National Laboratory research demonstrates that roofing materials experience accelerated aging equivalent to 15-20 years of normal weathering within just five years of Texas Panhandle exposure, making biannual professional inspections essential for system longevity.

Hail impact assessment requires specialized knowledge of material resistance ratings and damage progression patterns. Professional inspectors trained in IBHS FORTIFIED standards can distinguish between cosmetic granule loss and structural compromise that threatens waterproof integrity. Impact-resistant shingles like those meeting UL 2218 Class 4 ratings show significantly better performance in post-storm evaluations, but even these systems require professional assessment after severe weather events to document any warranty-affecting damage.

The inspection process culminates with detailed documentation that includes thermal imaging analysis, core sample evaluation for multi-layer systems, and fastener pull-out testing in critical areas. International Institute of Building Enclosure Consultants standards require that inspection reports include specific recommendations for immediate repairs, preventive maintenance scheduling, and long-term replacement planning based on remaining service life calculations adjusted for local climate factors.