Commercial property owners in Amarillo face constant challenges in maintaining their roofing systems, with hidden leaks representing one of the most costly and dangerous threats to building integrity. Traditional leak detection methods often fail to identify problems until water damage becomes visible, resulting in expensive repairs and potential business disruptions. Thermal imaging technology has revolutionized the commercial roofing industry by providing non-invasive, accurate detection of moisture intrusion and insulation deficiencies before they escalate into major problems.

Understanding Thermal Imaging Technology in Commercial Roofing

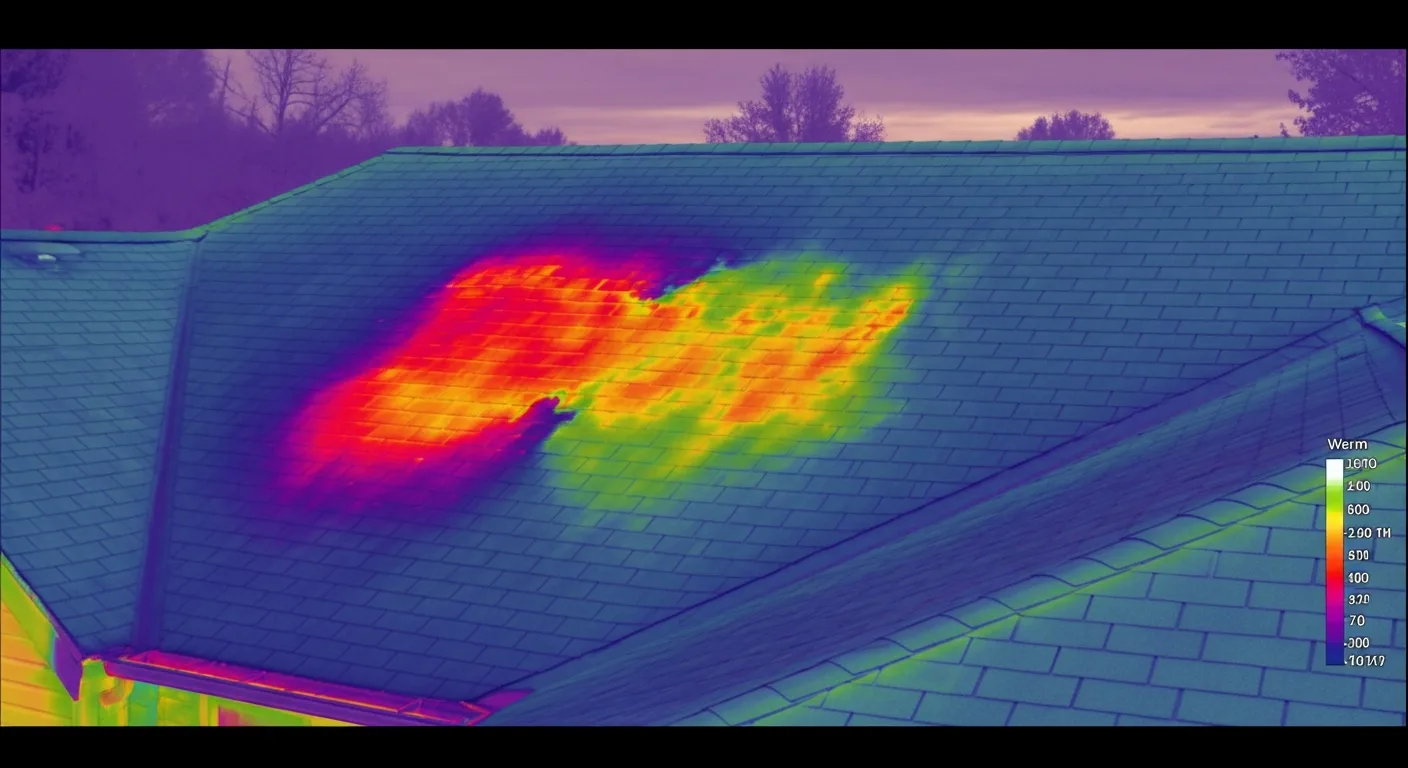

Thermal imaging, also known as infrared thermography, utilizes specialized cameras that detect heat patterns and temperature variations across roof surfaces. This advanced technology captures thermal radiation emitted by objects and converts it into visible images that reveal temperature differences invisible to the naked eye. When moisture infiltrates roofing materials, it creates distinct thermal signatures that trained professionals can identify and analyze.

The science behind thermal imaging relies on the principle that wet materials retain heat differently than dry materials. During temperature fluctuations throughout the day, areas with moisture will heat up and cool down at different rates compared to dry sections. These temperature variations appear as contrasting colors or patterns on thermal images, allowing roofing professionals to pinpoint problem areas with remarkable precision.

Modern thermal imaging cameras used by commercial roofing contractors can detect temperature differences as small as 0.1 degrees Celsius, making them incredibly sensitive tools for identifying even minor moisture intrusion. The National Roofing Contractors Association (NRCA) recognizes thermal imaging as a valuable diagnostic tool for roof condition assessment and preventive maintenance programs.

The Hidden Dangers of Undetected Commercial Roof Leaks

Commercial roof leaks often develop gradually, with water infiltration occurring for weeks or months before becoming apparent through visible signs like water stains, mold growth, or structural damage. This delayed detection can result in extensive property damage, increased repair costs, and potential health hazards for building occupants.

Structural Damage and Deterioration

When water penetrates roofing systems, it begins compromising structural elements immediately. Insulation becomes saturated, losing its thermal efficiency and adding significant weight to the roof deck. Steel components may begin corroding, while wooden structures face rot and decay. The longer these conditions persist, the more extensive and expensive the necessary repairs become.

According to the U.S. Department of Energy, compromised roof insulation can increase building energy costs by 25-40%, making early leak detection crucial for maintaining operational efficiency.

Indoor Air Quality and Health Concerns

Hidden moisture creates ideal conditions for mold and mildew growth, which can severely impact indoor air quality and pose health risks to employees, customers, and tenants. These biological contaminants can spread throughout HVAC systems, affecting entire buildings and creating liability concerns for property owners.

Professional commercial roof inspection services utilizing thermal imaging can identify moisture problems before they lead to these serious health and safety issues, protecting both property investments and building occupants.

How Thermal Imaging Detects Commercial Roof Leaks

The thermal imaging process for commercial roof leak detection involves systematic scanning of roof surfaces using handheld or drone-mounted infrared cameras. Professional technicians conduct these inspections during specific weather conditions and times of day to maximize detection accuracy.

Optimal Inspection Conditions

Thermal imaging inspections achieve best results when performed during temperature differential periods, typically in early morning or late evening hours. Clear skies for at least 24 hours prior to inspection ensure that solar heating doesn't interfere with accurate temperature readings. Wind speeds should remain below 15 mph to prevent convective cooling that could mask thermal signatures.

Professional roofing contractors understand these timing requirements and schedule thermal inspections accordingly to provide the most accurate assessments possible.

Identifying Thermal Signatures

Wet insulation and roofing materials exhibit distinct thermal patterns that trained thermographers can readily identify. During cooling periods, saturated areas retain heat longer than surrounding dry materials, appearing as warm spots on thermal images. Conversely, during heating cycles, wet areas may appear cooler due to evaporation effects.

Experienced technicians also look for thermal bridging patterns that indicate compromised insulation continuity, air leakage paths, and areas where structural elements may be conducting heat differently due to moisture exposure.

Advantages of Thermal Imaging Over Traditional Methods

Traditional leak detection methods often rely on visual inspections, water testing, or waiting for problems to manifest through interior damage. These approaches have significant limitations compared to thermal imaging technology.

Non-Invasive Detection

Unlike destructive testing methods that require cutting into roofing materials or removing membrane sections, thermal imaging provides comprehensive assessment without damaging existing roof systems. This non-invasive approach saves time, reduces costs, and eliminates the risk of creating new leak points during inspection.

Comprehensive Coverage

Thermal imaging cameras can scan large commercial roof areas quickly and efficiently, providing complete coverage that would be impossible with traditional spot-checking methods. This comprehensive approach ensures that no potential problem areas are overlooked during inspection.

The Insurance Institute for Business & Home Safety (IBHS) emphasizes the importance of comprehensive roof moisture detection in preventing catastrophic building failures and reducing insurance claims.

Early Problem Identification

Thermal imaging can detect moisture intrusion weeks or months before traditional methods would identify problems. This early warning capability allows property owners to address issues before they escalate into major repairs or cause secondary damage to building contents and operations.

Professional Thermal Imaging Services and Repair Solutions

While thermal imaging technology has become more accessible, professional interpretation of thermal data requires specialized training and experience. Certified thermographers understand how various factors affect thermal signatures and can distinguish between actual moisture problems and false readings caused by environmental conditions or roof surface variations.

Comprehensive Reporting and Documentation

Professional thermal imaging services provide detailed reports documenting identified problem areas, thermal images with temperature data, and recommended repair priorities. This documentation proves valuable for insurance claims, warranty issues, and long-term maintenance planning.

When thermal imaging reveals moisture intrusion, immediate commercial roof repair becomes essential to prevent further damage and minimize repair costs. Professional roofing contractors can develop targeted repair strategies based on thermal imaging findings, addressing specific problem areas efficiently and cost-effectively.

Integration with Preventive Maintenance Programs

Regular thermal imaging inspections should be integrated into comprehensive roof maintenance programs. Annual or bi-annual thermal surveys can track roof condition changes over time, identifying trends that may indicate developing problems or maintenance needs.

Modern roofing companies leverage advanced technology and expertise to provide integrated solutions that combine thermal imaging detection with prompt, professional repair services, ensuring commercial properties remain protected against water damage.

Maximizing Return on Investment Through Early Detection

The cost of thermal imaging inspections represents a fraction of potential repair expenses associated with undetected roof leaks. Property owners who invest in regular thermal imaging services often realize significant savings through early problem identification and preventive maintenance approaches.

Major roofing manufacturers like GAF and Owens Corning recognize thermal imaging as an essential tool for maintaining roof warranty compliance and extending system lifecycles.

For Amarillo commercial property owners, thermal imaging represents an invaluable investment in building protection, operational continuity, and long-term cost management. By partnering with experienced roofing professionals who utilize this advanced technology, businesses can maintain reliable roof systems while minimizing unexpected repair expenses and operational disruptions.

The extreme climate conditions in the Texas Panhandle make thermal imaging particularly valuable for commercial roof maintenance. With temperature swings that can exceed 60 degrees Fahrenheit in a single day and frequent hailstorms that can compromise membrane integrity, commercial properties face unique challenges that traditional inspection methods often miss. The National Severe Storms Laboratory data shows that the Texas Panhandle experiences some of the most severe hail activity in the nation, making proactive leak detection essential for maintaining building envelope performance.

For commercial single-ply membrane systems, thermal imaging proves especially effective in detecting moisture intrusion around penetrations, seams, and areas where membrane adhesion may have failed. Carlisle SynTec's technical guidelines emphasize that early detection of moisture infiltration can extend membrane life by 40-60% compared to reactive maintenance approaches. TPO and EPDM systems, which are prevalent in Amarillo's commercial market, show distinct thermal signatures when compromised, allowing certified thermographers to pinpoint problem areas with accuracy rates exceeding 95%.

The National Roofing Contractors Association (NRCA) recommends bi-annual thermal imaging surveys for commercial roofs in severe weather climates, with additional inspections following significant weather events. This proactive approach aligns with modern building envelope science principles that prioritize moisture management as the critical factor in roof system longevity. Professional thermal imaging surveys should be conducted by certified thermographers who understand both roofing systems and infrared technology applications.

Safety considerations during thermal imaging inspections are paramount, particularly on large commercial installations. OSHA fall protection standards require proper safety equipment and procedures when accessing roof areas for thermal surveys. The non-invasive nature of thermal imaging reduces the need for extensive roof walking and core sampling, minimizing safety risks while providing comprehensive diagnostic information. Additionally, International Institute of Building Enclosure Consultants (IIBEC) standards require that thermal imaging reports include environmental conditions, equipment specifications, and professional interpretations to ensure actionable maintenance recommendations.

Energy efficiency benefits of thermal imaging extend beyond leak detection to include identification of insulation deficiencies and thermal bridging issues. In Texas's extreme summer heat, where roof surface temperatures can exceed 160°F, maintaining proper insulation R-values becomes critical for building performance. Department of Energy studies indicate that addressing thermal deficiencies identified through infrared surveys can reduce cooling costs by 15-25% in commercial buildings, making thermal imaging surveys a cost-effective investment in both building protection and operational efficiency.