Building managers face constant pressure to control operational expenses while maintaining safe, functional facilities. One of the most effective strategies for reducing long-term roofing costs is implementing a comprehensive preventative inspection program. By catching minor issues before they escalate into major problems, building managers can significantly extend roof lifespan, avoid emergency repairs, and optimize their maintenance budgets.

The True Cost of Reactive Roofing Management

Many building managers operate under a reactive maintenance approach, addressing roofing issues only when problems become apparent. This strategy might seem cost-effective in the short term, but it often leads to exponentially higher expenses over time. According to the National Roofing Contractors Association, emergency roof repairs can cost three to five times more than planned maintenance activities.

When minor issues like loose flashing, small membrane punctures, or clogged drains go unaddressed, they create pathways for water infiltration. This moisture can damage insulation, structural elements, and interior finishes, transforming a simple repair into a complex restoration project. The ripple effects include business disruption, temporary relocation costs, and potential liability issues that extend far beyond the original roofing problem.

Consider the typical progression of a small roof leak: what begins as a $200 flashing repair can quickly evolve into thousands of dollars in structural damage, insulation replacement, and interior restoration. Professional roof inspection services can identify these vulnerabilities before they compromise building integrity and occupant safety.

Benefits of Preventative Roof Inspections

Early Problem Detection

Trained roofing professionals can identify potential issues that building managers might overlook during routine facility walkthroughs. These inspections reveal problems such as membrane deterioration, fastener backup, thermal movement damage, and drainage inadequacies. By documenting these conditions early, building managers can prioritize repairs based on urgency and budget availability, preventing minor issues from becoming major failures.

Extended Roof Service Life

Regular inspections coupled with timely maintenance can extend roof service life by 40-60% according to industry studies. The Department of Energy emphasizes that well-maintained commercial roofing systems not only last longer but also maintain their energy efficiency throughout their service life. This dual benefit reduces both replacement costs and ongoing energy expenses.

Warranty Protection

Most commercial roofing warranties require regular professional inspections and documented maintenance. Failing to meet these requirements can void warranty coverage, leaving building owners responsible for premature failures that should be covered by manufacturer guarantees. Preventative inspections ensure compliance with warranty terms while creating documentation that supports warranty claims when necessary.

Developing an Effective Inspection Schedule

The frequency of roof inspections depends on several factors including roof age, system type, local climate conditions, and building use. Generally, commercial roofs should receive professional inspections at least twice annually – typically in spring and fall – with additional inspections following severe weather events.

Spring inspections focus on identifying winter damage such as ice dam effects, thermal shock damage, and debris accumulation. Fall inspections prepare roofs for winter conditions by ensuring proper drainage, securing loose materials, and addressing any issues that could worsen during harsh weather. This schedule aligns with recommendations from the Federal Emergency Management Agency for commercial building preparedness.

Buildings with older roofing systems, complex configurations, or exposure to harsh environmental conditions may require more frequent inspections. Similarly, facilities housing sensitive equipment or operations should consider quarterly inspections to minimize any risk of weather-related disruptions.

What Professional Inspections Include

Comprehensive roof inspections examine all system components, including membrane condition, flashing integrity, drainage functionality, and structural elements. Inspectors document findings with photographs and detailed reports that help building managers understand current conditions and plan future maintenance activities.

Key inspection areas include penetration seals, expansion joints, parapet walls, equipment supports, and drainage components. Inspectors also evaluate interior conditions for signs of moisture infiltration and assess insulation performance. This comprehensive approach ensures that all potential problem areas receive appropriate attention.

Cost-Benefit Analysis of Preventative Programs

While preventative inspection programs require upfront investment, the return on investment typically ranges from 300-500% over a roof's service life. The Insurance Institute for Business & Home Safety has documented significant cost savings for commercial properties that implement proactive maintenance programs compared to those using reactive approaches.

Consider these typical cost comparisons for a 20,000 square foot commercial roof:

Reactive approach costs over 20 years might include emergency repairs averaging $15,000 annually, premature replacement at 15 years costing $200,000, and business disruption expenses of $25,000. Total costs could exceed $550,000.

Preventative approach costs include biannual inspections at $800 each, planned maintenance averaging $5,000 annually, and replacement at 25 years for $180,000. Total costs typically range around $330,000 – representing savings of over $200,000.

These calculations don't account for improved energy efficiency, reduced insurance claims, and enhanced property values that result from well-maintained roofing systems. Professional maintenance programs create additional value through optimized system performance and reduced operational risks.

Implementing Technology for Better Results

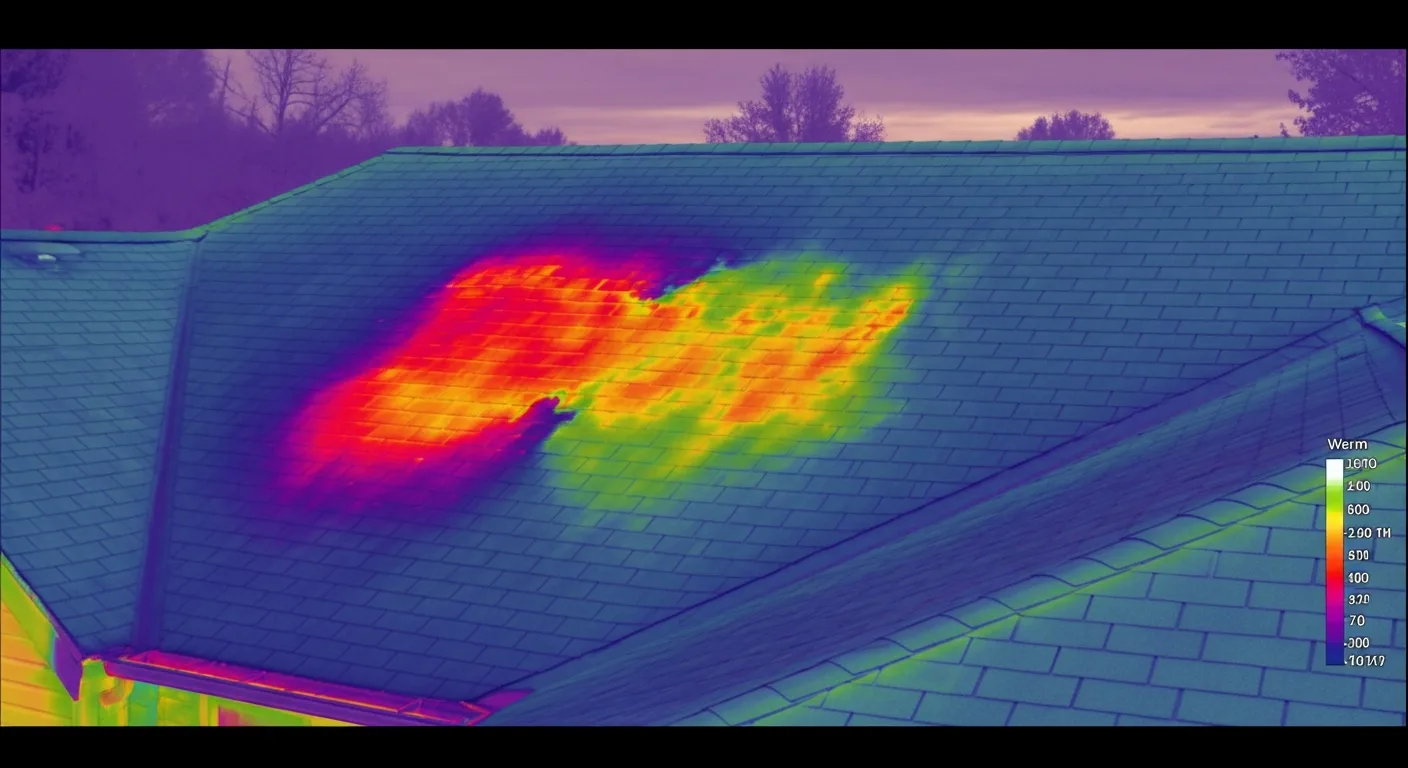

Modern inspection techniques incorporate advanced technologies that provide more accurate condition assessments. Thermal imaging identifies moisture intrusion and insulation deficiencies that aren't visible during standard visual inspections. Drone technology enables safer, more comprehensive evaluations of large or complex roof areas.

Digital documentation systems create detailed condition records that track changes over time, helping building managers identify trends and optimize maintenance schedules. These tools also facilitate communication with stakeholders by providing clear visual evidence of roof conditions and repair needs.

Integration with Building Management Systems

Progressive building managers integrate roof maintenance data with comprehensive facility management systems. This approach enables better resource allocation, improved planning coordination, and enhanced reporting capabilities. Integration also supports sustainability initiatives by optimizing roof performance and extending service life.

Selecting Qualified Inspection Providers

Effective preventative programs depend on qualified inspection providers who understand commercial roofing systems and local climate challenges. Look for contractors with relevant certifications, comprehensive insurance coverage, and established track records with similar facilities.

Reputable providers should offer detailed written reports, photographic documentation, and clear recommendations prioritized by urgency and impact. They should also maintain relationships with quality material suppliers and understand warranty requirements for various roofing systems.

Building managers should establish long-term relationships with trusted roofing professionals who understand their facilities and can provide consistent, reliable service. This continuity enables better condition tracking and more effective maintenance planning over time.

Ready to implement a cost-effective preventative inspection program for your commercial property? Contact our experienced team to develop a customized maintenance strategy that protects your investment while optimizing your roofing budget. Our comprehensive approach ensures your roofing systems deliver maximum value throughout their service life.

In the Texas Panhandle, building managers face unique challenges that make preventative inspections even more critical. The region's extreme weather patterns—including severe hailstorms, high winds exceeding 70 mph, and temperature fluctuations from below freezing to over 100°F—accelerate roof deterioration significantly. According to the National Severe Storms Laboratory, the Texas Panhandle sits in one of the nation's most active hail corridors, making regular inspections essential for early damage detection.

Professional preventative inspections should follow NRCA standards and occur at least twice annually—ideally in spring and fall—with additional checks after severe weather events. For commercial buildings with TPO or EPDM membranes, inspectors should examine seam integrity, membrane attachment, and thermal movement accommodations. Carlisle SynTec systems, commonly used in commercial applications, require specific inspection protocols to maintain warranty coverage and optimal performance in extreme temperature conditions.

Energy efficiency considerations are particularly important in the Texas Panhandle's climate. During inspections, building managers should assess roof reflectivity and thermal performance, as proper maintenance of cool roof systems can reduce cooling costs by 10-15%. The Cool Roof Rating Council provides standardized ratings for reflectivity and emissivity that help building managers make informed decisions about roof maintenance and replacement timing.

Documentation plays a crucial role in preventative inspection programs. IIBEC guidelines recommend maintaining detailed records including photographic evidence, measurement data, and repair histories. This documentation not only helps track deterioration patterns but also supports insurance claims and warranty enforcement. For buildings in high-wind zones like Amarillo, which falls under Wind Zone III requirements, proper documentation of wind uplift resistance and attachment integrity becomes even more critical for commercial insurance compliance.