Effective commercial roof maintenance in 2025 requires a systematic approach that combines traditional inspection methods with modern technology and sustainable practices. As building owners face increasing challenges from extreme weather, energy costs, and regulatory compliance, a comprehensive maintenance checklist becomes essential for protecting your investment and ensuring optimal performance throughout the year.

Pre-Season Preparation and Documentation

Starting your commercial roof maintenance program requires establishing a solid foundation of documentation and baseline assessments. Begin by gathering all existing roof warranties, previous inspection reports, and maintenance records. This historical data provides crucial insights into your roof's performance patterns and helps identify recurring issues that need special attention.

Create a detailed roof asset inventory that includes membrane type, installation date, drainage systems, and any penetrations or equipment mounted on the roof surface. Digital documentation with photographs and GPS coordinates of key areas will streamline future inspections and help track changes over time. The National Roofing Contractors Association recommends maintaining comprehensive records as part of any effective maintenance strategy.

Schedule your maintenance activities around seasonal weather patterns specific to the Texas Panhanain region. Spring and fall typically offer the best conditions for thorough inspections and repairs, while summer and winter maintenance should focus on storm preparation and emergency response protocols.

Monthly Visual Inspection Protocol

Implementing a monthly visual inspection routine helps identify potential problems before they become costly repairs. Train designated facility staff to recognize common warning signs and establish clear reporting procedures for any concerns discovered during routine walkthroughs.

Membrane and Surface Evaluation

Examine the roof membrane for signs of aging, cracking, blistering, or punctures. Look for areas where seams may be separating or where the membrane appears to be pulling away from penetrations. Pay special attention to high-traffic areas, equipment pads, and locations where maintenance personnel regularly access the roof.

Check for proper drainage by observing water flow patterns during and after rain events. Ponding water that remains on the roof surface for more than 48 hours after precipitation indicates drainage issues that require immediate attention. Our comprehensive commercial roof inspection services can provide detailed assessments of membrane condition and drainage performance.

Penetration and Flashing Assessment

All roof penetrations, including HVAC units, vents, skylights, and pipe penetrations, should be inspected for proper sealing and flashing condition. Look for gaps, cracks, or deteriorated sealants that could allow water infiltration. Equipment vibration and thermal expansion can cause seals to fail over time, making regular inspection critical.

Examine parapet walls, copings, and edge details for signs of movement or deterioration. These areas are particularly vulnerable to wind damage and thermal cycling, which can create entry points for moisture.

Quarterly Professional Inspections

While monthly visual inspections help catch obvious issues, quarterly professional inspections provide the expertise needed to identify subtle problems and assess overall roof condition. Professional roofers have the training and equipment necessary to safely access all areas of your commercial roof and conduct thorough evaluations.

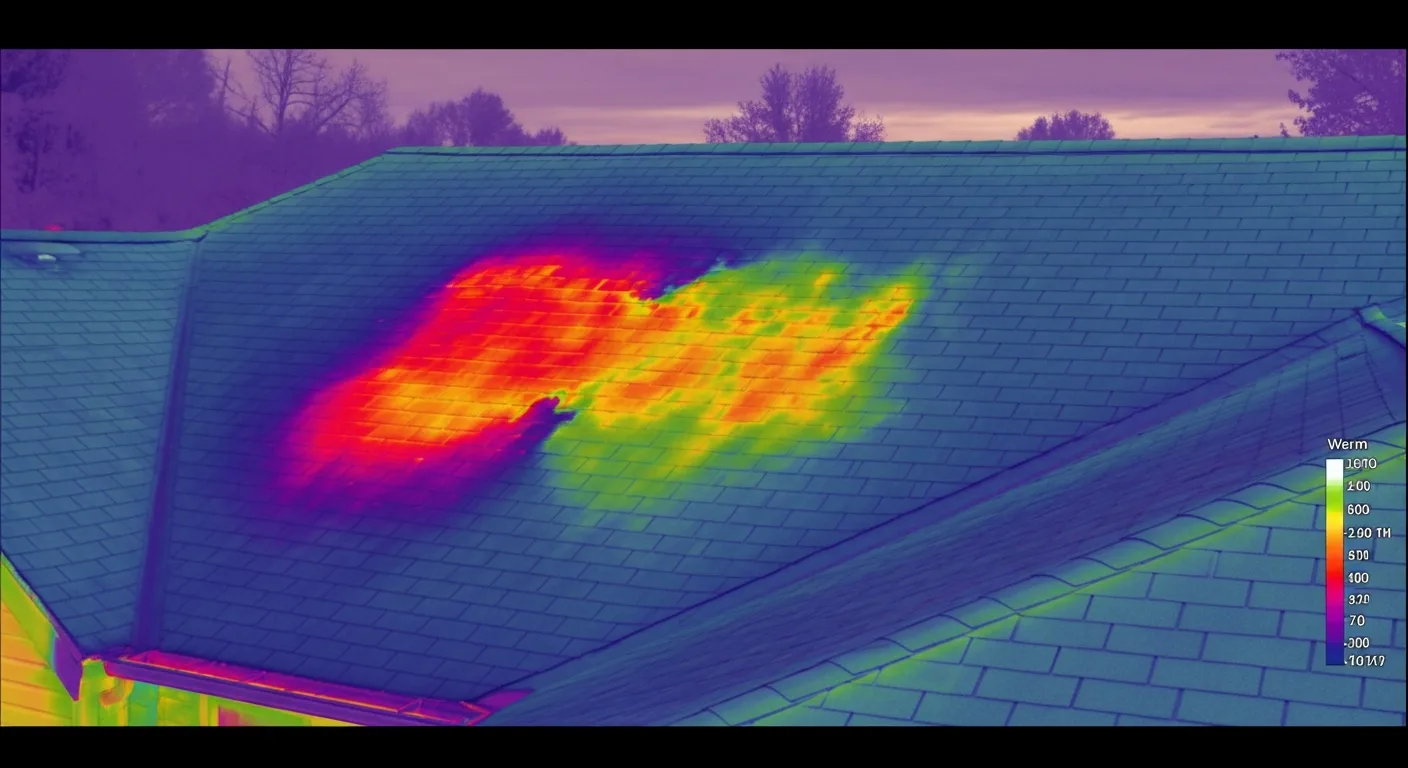

Professional inspections should include core sampling in suspected problem areas, moisture detection using infrared thermography or electrical impedance testing, and detailed documentation of any deficiencies found. The Department of Energy emphasizes the importance of regular professional assessments for maintaining energy efficiency and preventing costly failures.

These inspections should also evaluate the condition of insulation systems, vapor barriers, and structural components where accessible. Changes in energy costs or indoor comfort levels may indicate insulation problems that aren't visible from the roof surface.

Seasonal Maintenance Tasks

Spring Preparation

Spring maintenance focuses on preparing your roof system for the challenging weather conditions ahead. Clean all drains, gutters, and downspouts to ensure proper water management during heavy spring rains and summer thunderstorms. Remove any debris that accumulated over the winter months, paying particular attention to areas around equipment and penetrations.

Inspect and test all roof drains, including overflow drains and scuppers. Verify that drain strainers are in place and functioning properly. Consider upgrading to larger drains or additional drainage points if your current system shows signs of being overwhelmed during heavy rainfall events.

Schedule any necessary repairs identified during winter inspections before the severe weather season begins. This proactive approach prevents minor issues from becoming major problems during storms when emergency repairs are more expensive and difficult to coordinate.

Summer Storm Preparedness

Summer maintenance in the Texas Panhandle region must account for severe thunderstorms, hail, and high winds. Secure all loose equipment, signs, and temporary installations that could become projectiles during storms. Verify that emergency contact information is current and that your roofing contractor can respond quickly to storm damage.

Create a post-storm inspection checklist that can be safely implemented by facility staff from ground level or through accessible interior areas. Document any visible damage immediately for insurance purposes, but avoid accessing the roof surface until professional assessment confirms it's safe to do so.

Technology Integration and Modern Solutions

Modern commercial roof maintenance increasingly relies on technology to improve efficiency and accuracy. Drone inspections can safely access difficult areas and provide detailed photographic documentation of roof conditions. Thermal imaging cameras help identify insulation voids, moisture infiltration, and energy loss patterns that aren't visible to the naked eye.

Consider implementing IoT sensors and monitoring systems that provide real-time data on roof performance, including moisture levels, temperature variations, and structural movement. These systems can alert facility managers to developing problems before they cause significant damage.

Digital maintenance management platforms help track inspection schedules, document findings, and maintain compliance with warranty requirements. Cloud-based systems ensure that critical information remains accessible to all stakeholders and provides valuable data for making informed decisions about roof replacement timing and budgeting.

Compliance and Safety Considerations

Roof maintenance activities must comply with OSHA safety regulations and local building codes. Ensure that all personnel accessing the roof have proper safety training and equipment. Establish clear protocols for when professional contractors should be engaged rather than attempting maintenance with internal staff.

Stay informed about changing environmental regulations that may affect your roof system. Energy efficiency requirements, stormwater management regulations, and cool roof mandates can all impact maintenance priorities and upgrade decisions.

Our professional maintenance programs include safety compliance protocols and help ensure that all work meets current regulatory requirements while protecting your facility and personnel.

Budget Planning and Long-Term Strategy

Effective commercial roof maintenance requires adequate budget allocation and long-term planning. Develop a capital improvement plan that accounts for expected maintenance costs, major repairs, and eventual replacement needs. Industry data suggests that properly maintained commercial roofs can achieve their full design life, while neglected systems may fail prematurely and require expensive emergency replacement.

Track maintenance costs and roof performance metrics to identify trends and optimize your maintenance approach. Regular investment in preventive maintenance typically costs significantly less than reactive repairs and emergency roof replacement.

Consider the total cost of ownership when making maintenance decisions. Energy-efficient upgrades, improved drainage systems, and enhanced weather resistance features may have higher initial costs but provide long-term value through reduced operating expenses and extended roof life.

Partner with experienced commercial roofing professionals who understand local climate conditions and can provide reliable maintenance services throughout the year. Our comprehensive commercial roofing services include maintenance planning, emergency response, and long-term strategic guidance to help you maximize your roof system investment while minimizing unexpected costs and operational disruptions.

The Texas Panhandle's extreme weather conditions demand specialized attention to commercial roof maintenance protocols. With documented hail events exceeding 4 inches in diameter and sustained wind speeds regularly reaching 60+ mph, commercial buildings in Amarillo face unique challenges that require proactive maintenance strategies. Temperature fluctuations from summer highs exceeding 100°F to winter lows below freezing create thermal cycling stress that can accelerate membrane degradation and joint failure.

For commercial single-ply membrane systems, maintenance scheduling should align with SPRI guidelines for wind uplift resistance testing and seam integrity verification. TPO and EPDM membranes commonly used in Texas commercial applications require bi-annual inspections of heat-welded seams, particularly after severe weather events. Carlisle SynTec's technical bulletins recommend immediate post-storm assessments when hail exceeds 1-inch diameter, as membrane punctures may not be immediately visible but can lead to catastrophic leaks during subsequent rain events.

Energy efficiency considerations become critical during the brutal Texas summer months, where roof surface temperatures can exceed 160°F on black membranes. Cool Roof Rating Council data demonstrates that properly maintained reflective membranes can reduce cooling costs by 15-30% in hot climates. Regular cleaning of reflective surfaces and immediate repair of damaged coatings should be prioritized in maintenance schedules, particularly before peak summer months.

Safety protocols during maintenance activities must comply with OSHA fall protection standards, which are especially critical given the high winds common to the region. All maintenance personnel should utilize appropriate personal protective equipment and follow confined space entry procedures when inspecting internal drainage systems. Additionally, IIBEC best practices recommend scheduling non-emergency maintenance during periods of low wind velocity, typically early morning hours in the Panhandle region.