When facing a roof replacement, most property owners want to understand what drives the final price tag. While every project is unique, several key factors consistently have the most significant impact on replacement costs, often determining whether you'll spend $15,000 or $50,000+ on your new roof system.

What Roof Replacement Costs Really Mean

A roof replacement represents a major investment in your property's building envelope—the critical barrier protecting your structure from moisture intrusion, wind uplift forces, and thermal energy loss. Understanding cost factors helps you make informed decisions about materials, timing, and contractor selection while ensuring your new roof system delivers optimal performance and longevity.

The National Roofing Contractors Association emphasizes that focusing solely on initial costs often leads to poor long-term value. The most expensive component isn't always the roof itself—it's often the labor, structural modifications, or premium materials needed for your specific situation.

Primary Cost Drivers for Roof Replacement

Material Selection and Quality

Your choice of roofing materials typically represents 40-50% of total project costs, with dramatic price variations between options:

- Basic asphalt shingles: $100-200 per square (100 sq ft)

- Architectural shingles: $250-400 per square

- Impact-resistant shingles: $350-500 per square

- Metal roofing systems: $400-800 per square

- Premium materials (slate, tile): $800-1,500+ per square

For commercial applications, membrane systems like TPO, EPDM, and PVC each carry different price points, with cool roof technologies commanding premium pricing for their thermal reflectivity benefits.

Roof Size and Complexity

Square footage directly impacts material and labor costs, but roof complexity often matters more than total area. Simple gable roofs cost significantly less per square foot than complex designs featuring:

- Multiple roof planes and angles

- Dormers, valleys, and intersections

- Chimneys, skylights, and penetrations

- Steep pitches requiring specialized safety equipment

Complex roof geometries increase labor time, waste factors, and material requirements for proper flashing and waterproofing details.

Structural Requirements and Modifications

Existing roof structure condition significantly impacts replacement costs. Issues requiring additional investment include:

- Inadequate roof decking requiring plywood/OSB replacement

- Insufficient rafter sizing for heavier materials

- Missing or inadequate ventilation systems

- Code compliance upgrades for wind uplift resistance

- Insulation improvements to meet current R-value requirements

In storm-prone regions like the Texas Panhandle, structural upgrades often focus on enhancing wind resistance and impact protection, which can add $2,000-8,000 to project costs.

Labor Costs and Market Conditions

Labor typically represents 35-45% of total replacement costs, with significant regional variations based on:

Local Market Dynamics

Contractor availability, seasonal demand, and local wage rates create substantial cost variations. Post-storm periods often see 20-40% price increases due to high demand and contractor shortages.

Project Timing

Seasonal factors influence both material costs and contractor availability:

- Peak season (spring/summer): Highest demand and pricing

- Off-season (fall/winter): Potential savings of 10-20%

- Emergency replacements: Premium pricing for urgent work

Removal and Disposal

Tear-off complexity affects labor costs significantly. Factors include:

- Number of existing roof layers

- Material type and attachment method

- Disposal fees and landfill requirements

- Site accessibility for debris removal

Regional Considerations for High-Wind Areas

Properties in the Texas Panhandle face unique cost factors due to extreme weather conditions:

Enhanced Wind Resistance

Building codes in high-wind zones require additional fastening, enhanced sheathing, and impact-resistant materials. These upgrades typically add 15-25% to standard replacement costs but provide crucial protection against wind uplift forces exceeding 110 mph.

Hail-Resistant Materials

Impact-resistant shingles rated for UL 2218 Class 4 performance cost more initially but often qualify for insurance discounts. The Insurance Institute for Business & Home Safety research demonstrates that these materials significantly reduce hail damage claims.

Thermal Performance Requirements

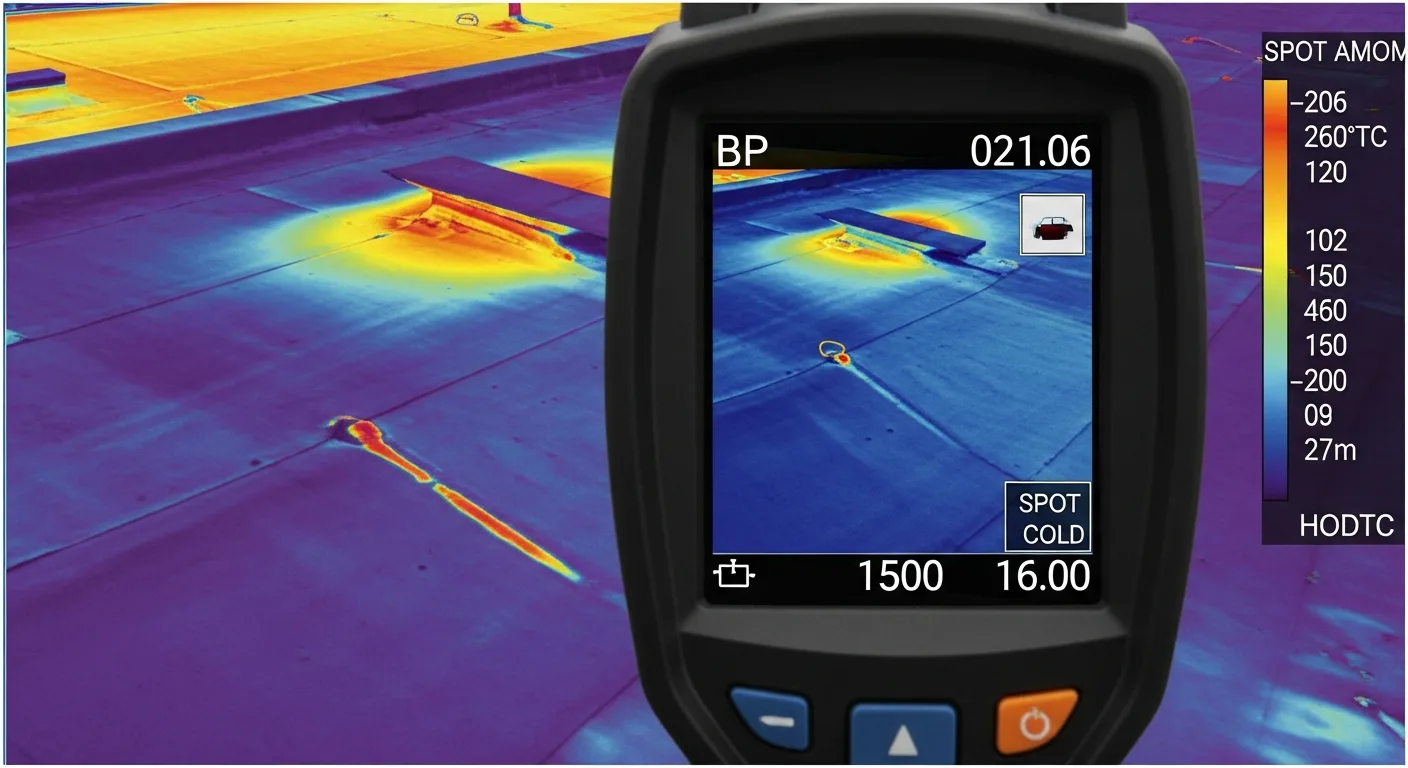

Extreme temperature fluctuations demand materials and installation methods designed for thermal cycling. Cool roof technologies, while more expensive, provide measurable energy savings in cooling-dominated climates.

Additional Cost Factors to Consider

Permit and Inspection Fees

Building permits typically cost $200-800, depending on project scope and local requirements. Some jurisdictions require structural engineering reviews for heavy materials or significant modifications.

Warranty and Quality Considerations

Extended manufacturer warranties and workmanship guarantees affect upfront costs but provide long-term value. Premium contractors often charge more but include comprehensive warranty coverage and superior installation quality.

Energy Efficiency Upgrades

Ventilation improvements, radiant barriers, and enhanced insulation increase initial costs but deliver ongoing energy savings. The Department of Energy estimates that proper attic ventilation can reduce cooling costs by 10-15%.

When to Call a Professional Roofer

Accurate cost estimation requires professional assessment of your specific situation. Experienced contractors evaluate structural conditions, code requirements, and material compatibility factors that significantly impact final pricing.

Professional contractors also help navigate insurance claims processes, ensuring maximum coverage for storm damage repairs. They understand local building codes, permit requirements, and installation best practices critical for roof system longevity.

Schedule a comprehensive roof inspection to receive accurate replacement cost estimates based on your property's specific requirements. Visit our residential roofing service page to learn more about our thorough evaluation process and transparent pricing approach. Understanding these cost factors helps you make informed decisions and invest wisely in your property's long-term protection.

In the Texas Panhandle, extreme weather conditions significantly amplify these cost factors. The region's notorious hail storms, with stones frequently exceeding 2 inches in diameter, require impact-resistant materials meeting UL 2218 Class 4 impact ratings. Wind speeds during severe weather events can reach 80+ mph, necessitating enhanced fastening patterns and materials rated for ASTM D3161 Class F wind resistance or higher.

Temperature extremes in Amarillo, ranging from sub-zero winters to 100°F+ summers, create thermal cycling stress that demands premium underlayment and ventilation systems. These conditions often push material costs 15-25% higher than national averages, as standard asphalt shingles may require upgrading to polymer-modified alternatives from manufacturers like Malarkey's Legacy series with NEX impact protection to ensure longevity.

Labor complexity increases substantially when addressing structural modifications required by current building codes. The International Building Code (IBC) updates now mandate enhanced wind uplift resistance for High Velocity Hurricane Zones, which applies to much of the Texas Panhandle. This often requires additional fasteners, upgraded deck sheathing, and reinforced edge details—modifications that can add $2-4 per square foot to project costs.

Safety compliance represents another significant cost driver often overlooked in initial estimates. OSHA fall protection requirements for residential roofing work over 20 feet mandate specialized equipment and training, while proper disposal of existing materials—particularly older shingles containing asbestos—requires certified handling procedures that can add $1-3 per square foot to removal costs.

Energy efficiency considerations also impact material selection and costs in Texas's extreme climate. ENERGY STAR rated cool roofing products with high solar reflectance can reduce cooling costs by 10-15% annually, making the higher upfront investment financially beneficial over the roof's lifespan, particularly given the Panhandle's intense UV exposure and extended cooling seasons.