Property owners in hail-prone regions like the Texas Panhandle often seek additional protection beyond standard roofing materials. Roof coatings have emerged as a popular solution, but many wonder whether these protective layers can truly shield their investment from future hail events. Understanding how coatings interact with impact forces and which systems offer the best protection is crucial for making informed decisions about your roof system's resilience.

What Roof Coatings Are and Why Impact Resistance Matters

Roof coatings are liquid-applied membranes that cure to form a seamless, protective layer over existing roofing materials. These systems serve multiple functions within the building envelope, including waterproofing, UV protection, and thermal reflectivity enhancement. However, their role in hail protection involves complex interactions between material properties, application thickness, and substrate characteristics.

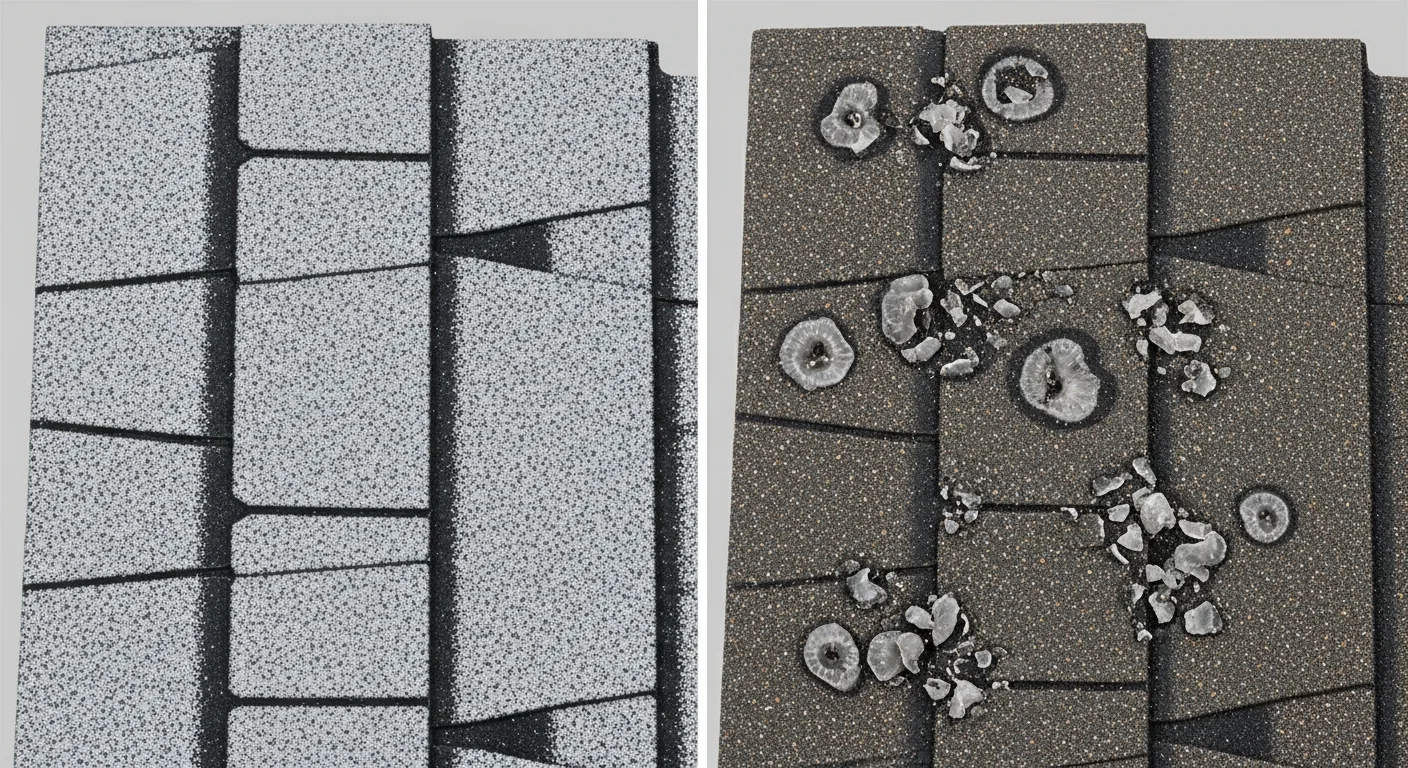

Impact resistance in roofing systems is measured using standardized tests, including ASTM D3746 for impact resistance of bituminous roofing systems. These tests simulate hail impacts using steel balls dropped from specific heights, providing measurable data on how materials respond to sudden impact forces. The results help determine a system's ability to resist puncture, cracking, or other damage that could compromise the roof's weatherproofing capabilities.

For commercial membrane systems like TPO, EPDM, and PVC, coatings can provide an additional protective barrier that distributes impact forces across a wider area. This distribution effect reduces the concentrated stress that hailstones typically create when striking roofing materials directly.

Key Factors That Determine Coating Effectiveness Against Hail

Coating Type and Composition

Different coating chemistries offer varying levels of impact resistance. Silicone coatings typically provide excellent flexibility and can absorb impact energy without cracking, making them particularly effective for hail protection. Acrylic coatings, while offering good adhesion and reflectivity, may be more susceptible to damage from larger hailstones due to their harder cure profile.

Polyurethane coatings often strike a balance between flexibility and toughness, providing moderate impact resistance while maintaining excellent adhesion to various substrates. The specific formulation and additives within each coating type significantly influence their protective capabilities.

Application Thickness and Coverage

Coating thickness directly impacts impact resistance, with thicker applications generally providing better protection. Most manufacturers specify minimum mil thickness requirements, but increasing thickness beyond these minimums can enhance hail resistance. However, excessive thickness can lead to application issues and reduced flexibility, creating a balance between protection and performance.

Uniform coverage is equally critical, as thin spots or holidays in the coating create vulnerability points where hailstones can cause localized damage. Professional application ensures consistent mil thickness across the entire roof system.

Substrate Condition and Support

The underlying roofing material plays a crucial role in overall hail resistance. A coating applied over a deteriorated or compromised substrate cannot provide optimal protection. Impact forces transfer through the coating to the substrate below, meaning the entire roof system must work together to resist hail damage.

Rigid substrates like concrete or properly supported metal decking provide better impact resistance than flexible membranes with insufficient support. This relationship between coating and substrate emphasizes the importance of comprehensive roof system evaluation before coating application.

Coating Systems That Offer Superior Hail Protection

Impact-Resistant Formulations

Several manufacturers have developed coating systems specifically engineered for enhanced impact resistance. These formulations typically incorporate elastomeric properties that allow the coating to deform under impact and return to its original shape without permanent damage.

GAF's UniSil silicone coating system exemplifies this approach, offering high elongation properties that help dissipate impact energy. Similarly, other major manufacturers have developed specialized formulations that balance impact resistance with other performance requirements like thermal reflectivity and moisture resistance.

Multi-Layer Systems

Some coating applications involve multiple layers with different properties, creating a composite system optimized for various environmental challenges. A typical multi-layer approach might include a base coat for adhesion and moisture sealing, followed by a reinforcement layer, and topped with a finish coat designed for UV and impact resistance.

These systems often incorporate reinforcing fabrics or granules that enhance impact resistance while maintaining the seamless nature of liquid-applied systems. The combination of materials and layers provides redundancy that single-coat systems cannot match.

How Coatings Perform in the Texas Panhandle's Severe Weather Environment

The Texas Panhandle's climate presents unique challenges that affect coating performance and hail protection effectiveness. Extreme temperature fluctuations cause thermal cycling that can stress coating materials, while high winds create uplift forces that interact with impact resistance properties.

Hailstorms in this region often feature large hailstones (1-3 inches in diameter) with high kinetic energy due to strong updrafts in supercell thunderstorms. This combination requires coating systems that can withstand significant impact forces while maintaining flexibility across wide temperature ranges.

The region's intense UV exposure also affects coating longevity and performance. Coatings must maintain their impact-resistant properties even after years of solar radiation, making UV stability a critical factor in long-term hail protection.

Wind-driven hail adds another dimension to the protection challenge, as impacts occur at angles rather than straight down. This dynamic loading requires coatings that can resist shear forces in addition to perpendicular impact forces.

Cool Roof Benefits and Hail Resistance

Many modern coating systems offer "cool roof" properties through high thermal reflectivity, which can indirectly enhance hail resistance. By keeping roof surface temperatures lower, these coatings reduce thermal stress on the roofing system and maintain material flexibility that aids in impact resistance.

The Department of Energy recognizes cool roofs as effective tools for energy efficiency, and their thermal management properties can help maintain coating integrity during severe weather events.

Limitations and Realistic Expectations for Coating Protection

While roof coatings can significantly enhance hail resistance, they are not miracle solutions that eliminate all damage risk. Large hailstones (greater than 2 inches) can overwhelm even the best coating systems, particularly when combined with high winds and multiple impacts.

Coatings work best as part of a comprehensive approach to hail resistance that may include impact-resistant shingles, proper deck support, and regular maintenance. They should be viewed as enhancing the roof system's resilience rather than providing complete immunity to hail damage.

Age and weathering also affect coating performance. Even the most durable coatings will gradually lose some impact resistance over time as UV exposure and thermal cycling take their toll. Regular inspection and recoating maintain optimal protection levels.

When to Call a Professional Roofer

Determining whether roof coatings are appropriate for your hail protection needs requires professional evaluation of your existing roof system, local weather patterns, and building requirements. A qualified roofing contractor can assess substrate condition, recommend appropriate coating systems, and ensure proper application for maximum effectiveness.

If your property has experienced hail damage, professional inspection becomes even more critical. Hidden damage beneath the surface may compromise coating adhesion and performance, requiring repairs before coating application. To learn more about comprehensive storm damage assessment, visit our hail and wind damage repair page.

For commercial properties with membrane systems, coating applications should align with manufacturer warranty requirements and building codes. Professional contractors understand these requirements and can recommend systems that maintain warranty coverage while enhancing protection.

Contact our experienced team for a thorough roof inspection and coating consultation. Our expertise in Texas Panhandle weather conditions and proven coating systems helps property owners make informed decisions about protecting their investment against future hail events.

The Roof Coatings Manufacturers Association (RCMA) provides specific guidelines for coating systems designed to enhance hail resistance. Premium elastomeric and acrylic coatings can absorb and redistribute impact energy when applied at proper thickness - typically 20-40 mils for maximum protection. However, the effectiveness varies significantly based on the underlying substrate and local climate conditions.

In the Texas Panhandle, where National Severe Storms Laboratory data shows hail events frequently produce stones exceeding 1.75 inches in diameter, coating performance must be evaluated against extreme impact scenarios. The region's intense UV exposure and temperature fluctuations - often exceeding 100°F in summer - can affect coating elasticity and impact resistance over time. Silicone-based systems typically maintain better flexibility in these conditions compared to acrylic alternatives.

For commercial applications, SPRI standards recommend impact testing per ASTM D3746 and D4272 protocols before coating application. The substrate condition plays a crucial role - aged EPDM or TPO membranes may not provide adequate backing for effective impact distribution. Additionally, Insurance Institute for Business & Home Safety research indicates that while coatings can reduce minor hail damage, they cannot prevent punctures from severe impact events that would damage the underlying membrane.

Safety considerations during coating application in Texas heat are critical. OSHA guidelines require specific precautions when surface temperatures exceed 150°F, common on dark roofing materials during summer months. Professional application ensures proper mil thickness and coverage, which directly affects impact performance. Property owners should also verify that coating modifications don't void existing roof warranties or affect insurance coverage, particularly important given Texas Windstorm Insurance Association requirements for coastal and high-wind areas.