Every day your business operates under a compromised roof is a day you're gambling with catastrophic downtime. In the Texas Panhandle's unforgiving climate, where hail storms can strike with little warning and temperature swings exceed 100°F annually, a failing commercial roof isn't just an inconvenience—it's a business continuity crisis waiting to happen. When moisture intrusion finally breaches your building envelope, the resulting operational shutdown, inventory damage, and lost revenue can cost 10-15 times more than a proactive roof replacement. The question isn't whether you can afford to replace your roof, but whether you can afford not to act before emergency conditions force an unplanned closure.

When Roof Issues Require Immediate Professional Attention

Recognizing the critical indicators that demand professional intervention can mean the difference between planned downtime and operational disaster. Multiple membrane seams showing separation, ponding water that persists beyond 48 hours after precipitation, or visible daylight through the roof structure signal immediate action requirements. Interior water damage, even minor staining, indicates moisture intrusion that compromises your building envelope's integrity.

The National Roofing Contractors Association emphasizes that commercial roofs showing these symptoms typically fail within 6-18 months without intervention. In Amarillo's climate, where thermal cycling accelerates deterioration and severe weather events occur with increasing frequency, this timeline often compresses significantly. Temperature fluctuations exceeding 60°F in a single day create expansion and contraction cycles that rapidly worsen existing vulnerabilities.

Don't wait for emergency conditions to dictate your timeline. When professional inspection reveals systematic failure across multiple roof sections, membrane brittleness, or compromised insulation values below acceptable R-value thresholds, immediate planning for replacement protects against uncontrolled business interruption.

Key Decision Factors: Strategic Planning for Minimal Disruption

Successful commercial roof replacement with minimal downtime hinges on three critical decision factors: timing strategy, phased installation approach, and comprehensive contingency planning. Traditional roof-over installations can reduce disruption by 40-60% compared to complete tear-offs, though building codes and structural capacity must support this approach.

Timing Considerations: Amarillo's optimal roof replacement window typically spans late September through early November and March through early May, avoiding both peak summer heat and severe weather seasons. However, emergency replacements can't wait for perfect conditions. Professional contractors utilizing weather monitoring systems and flexible scheduling can work around forecast limitations while protecting your operations.

Phased Installation Strategy: Sectional replacement allows portions of your facility to remain operational while work progresses on isolated roof areas. This approach works particularly well for warehouse, manufacturing, and retail facilities where operations can temporarily relocate within the building footprint. Critical areas like server rooms, production lines, or customer-facing spaces receive priority protection during transition periods.

Cost Analysis and ROI Justification: Lifecycle cost analysis reveals that planned replacement typically costs 30-40% less than emergency repairs while providing superior long-term performance. Energy-efficient membrane systems meeting Energy Star thermal reflectivity standards can reduce cooling costs by 15-25% annually, creating measurable ROI that offsets installation expenses within 3-5 years.

Material and System Recommendations for Operational Continuity

Selecting roofing systems specifically engineered for rapid installation while maintaining superior performance standards minimizes business disruption without compromising quality. Single-ply membrane systems, particularly TPO and EPDM configurations, offer installation speeds 2-3 times faster than traditional built-up roofing while providing enhanced wind uplift resistance critical for Texas Panhandle conditions.

Thermoplastic Polyolefin (TPO) Systems: Heat-welded seams create watertight connections that eliminate the curing time required by adhesive-based systems. Installation crews can complete 8,000-12,000 square feet per day under optimal conditions, significantly reducing project timelines. Superior thermal reflectivity helps moderate interior temperatures during installation, maintaining more comfortable working conditions for continued operations.

Modified Bitumen Solutions: Self-adhering membrane systems eliminate torch application requirements, reducing fire risk and allowing installation in occupied buildings. These systems perform exceptionally well in temperature extreme environments, maintaining flexibility at low temperatures while resisting flow at summer peaks exceeding 110°F.

Metal Roofing Applications: Standing seam metal systems provide exceptional longevity with installation speeds that minimize disruption timeframes. Structural metal roofing can often install directly over existing systems, eliminating tear-off requirements that create the most significant operational disruption.

For comprehensive system recommendations specific to your facility type and operational requirements, see our commercial roofing services page for detailed technical specifications and performance comparisons.

What to Expect During the Professional Replacement Process

A well-orchestrated commercial roof replacement follows a systematic approach designed to minimize operational disruption while maintaining safety standards and quality control. Professional contractors begin with comprehensive pre-construction planning that identifies potential disruption points and develops mitigation strategies specific to your business operations.

Phase 1: Pre-Construction Planning (1-2 weeks): Detailed facility assessment, material procurement, permit acquisition, and coordination with building management systems. Weather monitoring integration ensures installation proceeds only under favorable conditions. Critical system protection plans cover HVAC equipment, electrical components, and sensitive operational areas.

Phase 2: Preparation and Protection (1-3 days): Temporary weather protection installation, equipment staging, and operational area isolation. Professional-grade containment systems prevent debris infiltration into work areas while maintaining access to essential building functions.

Phase 3: Installation Execution (3-10 days, depending on scope): Systematic roof removal and replacement following predetermined sequences that maintain building envelope integrity. Daily progress reports keep management informed of completion percentages and potential weather-related adjustments.

Phase 4: Final Protection and Commissioning (1-2 days): Quality assurance testing, warranty documentation, and complete cleanup with final inspection to ensure no operational disruption remnants remain.

Throughout this process, professional contractors maintain 24/7 emergency response capability and provide temporary weather protection if unexpected conditions arise. This comprehensive approach typically reduces total project time by 25-35% compared to standard installation practices.

Why Choosing the Right Contractor Makes All the Difference

Contractor selection directly impacts both project success and operational continuity during replacement. Experienced commercial roofing specialists understand the critical relationship between installation efficiency and business operations, employing strategies that minimize disruption while maintaining uncompromising quality standards.

Operational Continuity Expertise: Professional contractors specializing in occupied building installations possess specific training and equipment for maintaining business operations during construction. This includes temporary weatherization systems, contamination control protocols, and flexible scheduling that accommodates critical business functions.

Insurance and Warranty Considerations: Comprehensive general liability coverage, workers' compensation protection, and manufacturer-backed warranty programs protect your business investment. Many insurance providers offer premium reductions for facilities with recently replaced roofing systems that meet current wind resistance and energy efficiency standards.

Emergency Response Capability: Established contractors maintain emergency response teams and material stockpiles for immediate weather protection if conditions change during installation. This capability proves essential in the Texas Panhandle's unpredictable weather environment where severe storms can develop rapidly.

Code Compliance and Permitting: Professional contractors navigate complex commercial building codes, ensuring installations meet current energy efficiency requirements, wind uplift standards, and accessibility provisions. Proper permitting prevents project delays and ensures insurance coverage remains valid throughout the replacement process.

For locations throughout the Texas Panhandle region, check our service area pages for availability and local project portfolio examples demonstrating successful minimal-disruption installations.

Your business can't afford to wait for roof failure to force emergency action. CRS Roofing & Construction specializes in commercial roof replacement projects that maintain operational continuity while delivering superior long-term performance. Our experienced project management team coordinates every aspect of installation to minimize disruption, from initial assessment through final commissioning. Contact us today at (806) 358-7663 for a comprehensive facility assessment and customized replacement timeline that protects your bottom line. Don't let a failing roof decide your business schedule—take control with professional planning that keeps your operations running while securing your facility's future.

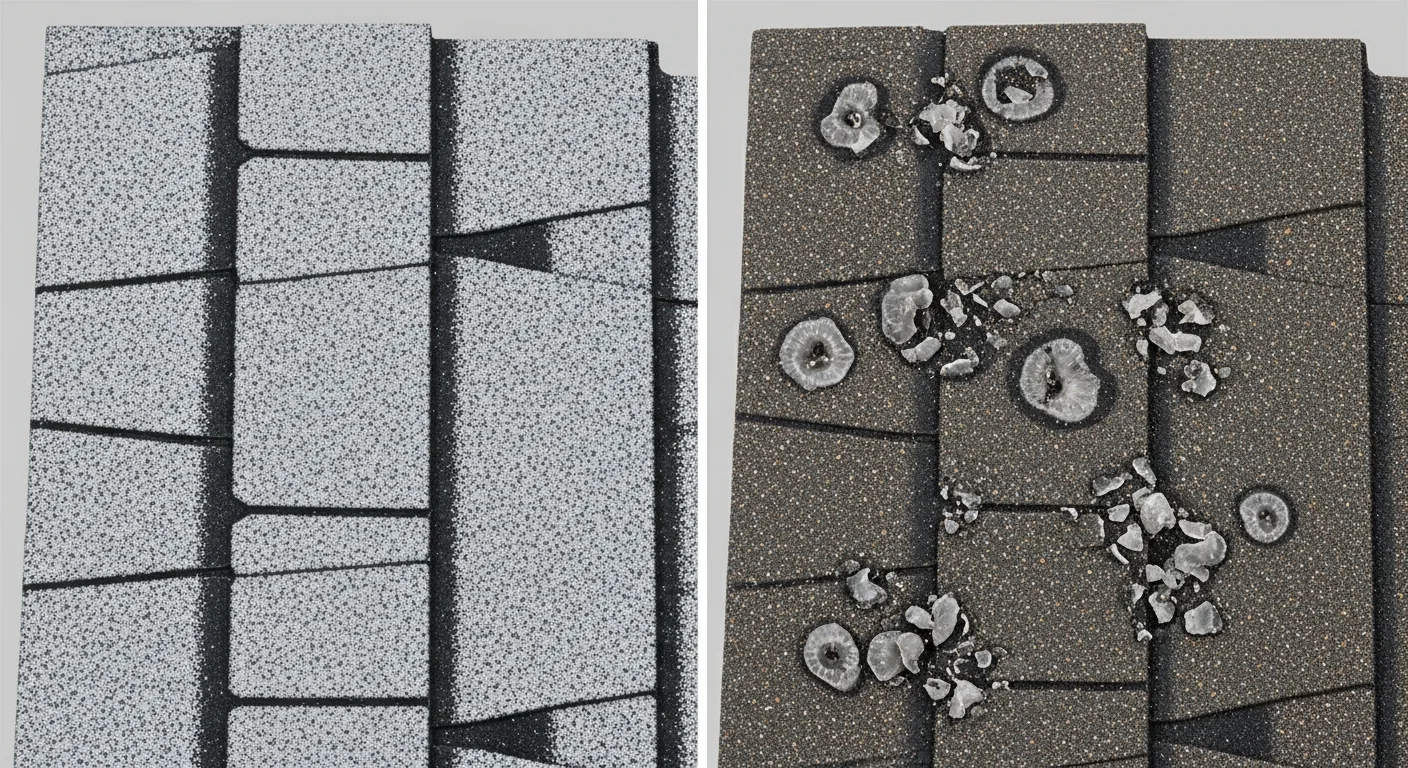

The Texas Panhandle's extreme climate conditions create unique challenges that demand specific material specifications and installation protocols. With NOAA data showing Amarillo experiencing winds exceeding 74 mph annually and hail events producing stones larger than 2 inches in diameter, commercial roofing systems must meet stringent impact resistance and wind uplift requirements. For TPO and EPDM membrane systems, this typically means specifying materials with a minimum thickness of 60 mils and Sure-Weld TPO systems rated for Class A fire resistance and high wind uplift ratings to withstand the region's severe weather patterns.

Temperature differentials in the Texas Panhandle, ranging from sub-zero winters to summers exceeding 110°F, create thermal expansion and contraction cycles that can compromise membrane integrity within 5-7 years without proper system design. Single Ply Roofing Industry (SPRI) standards recommend mechanically fastened systems with enhanced attachment patterns for buildings in high-wind zones, requiring 20% more fasteners per square than standard installations. This specification becomes critical when planning replacement schedules, as inadequate fastening patterns often contribute to catastrophic membrane failures during severe weather events.

Safety protocols during commercial roof replacement must align with OSHA fall protection standards, particularly given the Texas Panhandle's high-wind environment that can create additional hazards during installation. Professional contractors implement comprehensive safety management systems including personal fall arrest systems, guardrail systems, and safety net systems rated for 5,000-pound minimum breaking strength. These protocols become especially critical when coordinating phased replacement schedules designed to minimize business disruption.

Energy efficiency considerations play a crucial role in material selection for Texas Panhandle commercial properties, where cooling costs can represent 40-60% of annual energy expenses. Cool Roof Rating Council data demonstrates that highly reflective membrane systems with solar reflectance values exceeding 0.70 and thermal emittance above 0.75 can reduce roof surface temperatures by 50-80°F compared to conventional dark-colored systems. This temperature reduction translates to measurable decreases in HVAC demand and extends membrane service life by reducing thermal stress cycles.

Code compliance requirements in Texas mandate adherence to International Building Code wind load provisions, with commercial structures in the Amarillo region classified as Wind Zone III, requiring enhanced structural design and attachment specifications. These requirements directly impact replacement scheduling, as inadequate structural analysis during the planning phase can result in costly delays when building officials identify non-compliant installation methods or inadequate structural capacity for new roofing systems.