The Texas Panhandle presents some of the most challenging weather conditions for roofing systems in North America. With frequent hailstorms, sustained winds exceeding 70 mph, and extreme temperature fluctuations, choosing the right roofing materials isn't just about aesthetics or initial cost—it's about protecting your investment and ensuring your building envelope can withstand decades of severe weather exposure.

Understanding Weather-Related Roofing Challenges in Storm-Prone Areas

High-wind and hail-prone regions like the Texas Panhandle demand roofing materials that can resist multiple forms of severe weather damage. Wind uplift resistance becomes critical when sustained winds reach 60-80 mph, while hail impact resistance determines whether your roof system survives the golf ball and baseball-sized hail common to this region.

The combination of these weather extremes creates unique challenges for roof system lifespan. Materials must not only resist immediate impact damage but also maintain their structural integrity and weather-sealing properties through repeated thermal cycling, UV exposure, and moisture intrusion attempts. Understanding these dynamics helps property owners make informed decisions about long-term durability and performance.

Key Performance Metrics for Storm Resistance

When evaluating roofing materials for severe weather regions, several performance standards indicate superior durability:

- Impact resistance ratings: UL 2218 Class 3 and Class 4 classifications for hail resistance

- Wind resistance: ASTM D3161 and D7158 testing for wind uplift performance

- Fire resistance: Class A fire ratings for wildfire-prone areas

- Thermal performance: Cool roof properties and thermal reflectivity for energy efficiency

Top-Performing Residential Roofing Materials for Severe Weather

Impact-Resistant Asphalt Shingles

Modern impact-resistant shingles represent significant advancement in residential roofing technology. GAF's Timberline HDZ shingles and similar products from major manufacturers incorporate polymer-modified asphalt and reinforced backing materials that achieve UL 2218 Class 4 impact resistance.

These shingles can withstand 2-inch diameter steel balls dropped from 20 feet without cracking—equivalent to golf ball-sized hail at terminal velocity. The enhanced granule adhesion and flexible backing material also provide superior wind uplift resistance, often exceeding 130 mph wind ratings when properly installed.

Metal Roofing Systems

Standing seam metal roofing and concealed fastener systems offer exceptional longevity in high-wind areas. Quality steel and aluminum roofing materials typically carry wind resistance ratings of 140-180 mph, while their smooth profiles reduce wind uplift compared to traditional shingle systems.

Metal roofing's impact resistance varies by gauge and substrate, but most residential metal roofing easily achieves Class 3 impact ratings, with many reaching Class 4 when installed over appropriate decking materials. The thermal reflectivity of metal roofing also provides energy efficiency benefits in the intense Texas sun.

Synthetic and Composite Materials

Synthetic slate and composite shingles engineered from recycled materials and advanced polymers offer impressive durability metrics. These materials often exceed traditional materials in both impact resistance and wind uplift performance while providing the aesthetic appeal of natural materials without the weight and fragility concerns.

Commercial Membrane Systems Built for Extreme Weather

TPO and PVC Single-Ply Membranes

Thermoplastic polyolefin (TPO) and polyvinyl chloride (PVC) membranes dominate commercial roofing in severe weather regions for good reason. These single-ply systems, when properly adhered or mechanically fastened, provide exceptional wind uplift resistance and puncture resistance.

Quality TPO systems can achieve wind uplift ratings exceeding 300 pounds per square foot, while their white or light-colored surfaces provide excellent thermal reflectivity. The heat-welded seams create watertight barriers that resist moisture intrusion even under extreme weather conditions.

Modified Bitumen Systems

SBS (styrene-butadiene-styrene) modified bitumen offers superior flexibility and self-healing properties that make it ideal for buildings experiencing thermal cycling and minor impact damage. The polymer modification allows these systems to remain flexible at low temperatures while resisting flow at high temperatures.

When installed in multi-ply configurations with proper base sheets and cap sheets, modified bitumen systems provide redundant waterproofing layers that maintain building envelope integrity even if the top layer experiences minor damage.

EPDM Rubber Roofing

Ethylene propylene diene monomer (EPDM) rubber roofing excels in extreme temperature conditions and provides excellent hail resistance due to its inherent flexibility. Quality EPDM systems maintain their elasticity through wide temperature ranges, preventing the thermal stress cracking common in more rigid materials.

Installation and Design Factors That Maximize Material Performance

Even the highest-quality roofing materials can fail prematurely without proper installation and design considerations. In high-wind regions, enhanced attachment methods, appropriate fastener spacing, and proper edge securement become critical for maintaining wind uplift resistance throughout the roof system lifespan.

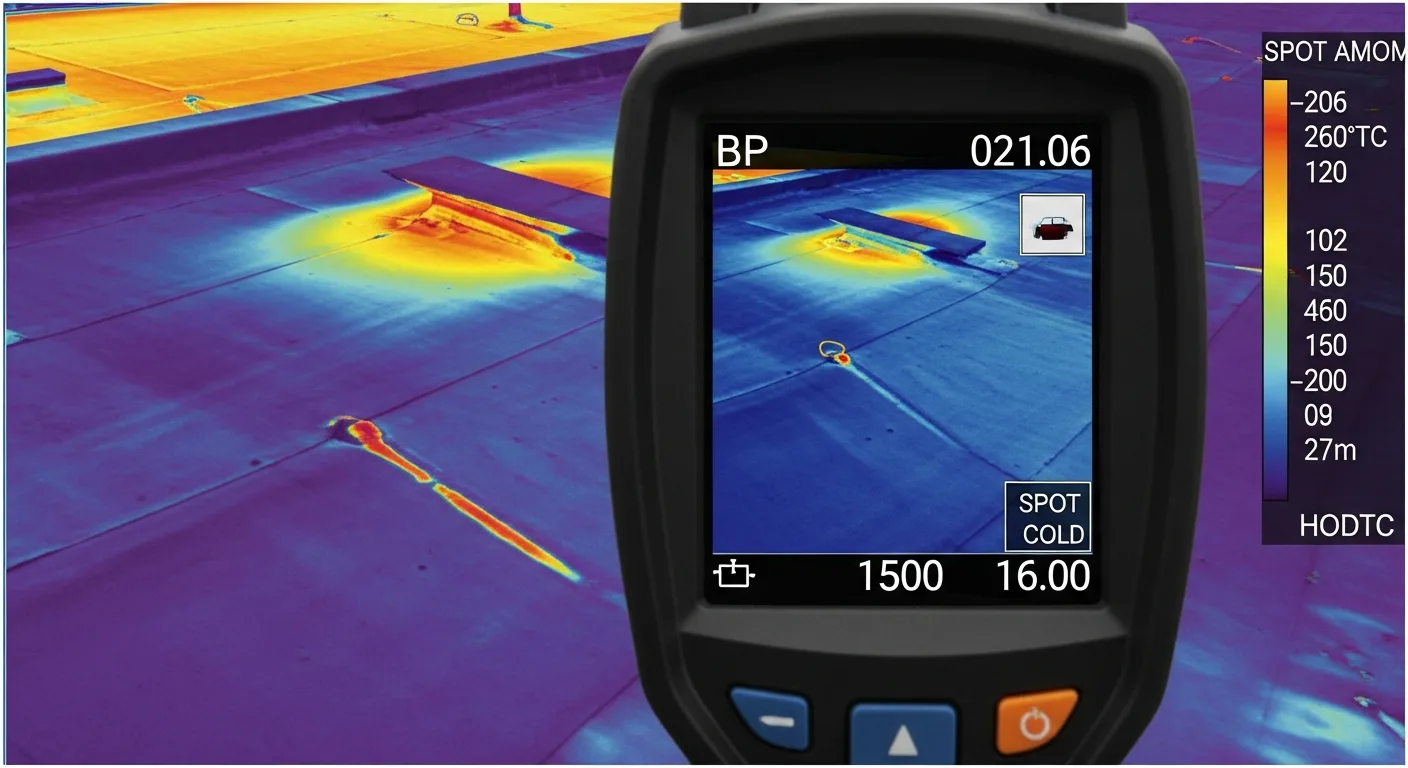

Drainage dynamics also play a crucial role in material longevity. Ponding water accelerates deterioration in all roofing materials, making proper slope design and drainage system maintenance essential for maximizing material performance. Commercial buildings especially benefit from primary and secondary drainage systems that prevent water accumulation during intense rainfall events.

Warranty Requirements and Considerations

Material warranties in severe weather regions often include specific installation requirements and wind/hail coverage limitations. Understanding these warranty requirements helps ensure your investment receives maximum protection. Many manufacturers now offer enhanced warranties for impact-resistant materials when installed by certified contractors using approved methods.

The National Roofing Contractors Association provides detailed guidelines for installation practices that maximize material performance and warranty coverage in severe weather regions.

How Storm-Resistant Materials Perform in Texas Panhandle Conditions

The unique combination of high winds, large hail, and extreme UV exposure in the Texas Panhandle creates the ultimate testing ground for roofing materials. Materials that perform well in this environment typically exceed performance expectations in milder climates.

Local weather patterns, including the frequency of supercell thunderstorms and the potential for straight-line winds, make impact resistance and wind uplift performance equally important. The National Weather Service's Amarillo office regularly documents weather events that test roofing systems to their limits.

Property owners in this region also benefit from understanding how thermal cycling affects material selection. The extreme temperature swings from winter lows below 0°F to summer highs exceeding 100°F require materials with excellent thermal stability and expansion/contraction characteristics.

When to Call a Professional Roofer for Material Selection

Selecting appropriate roofing materials for severe weather regions requires expertise in local building codes, manufacturer specifications, and installation requirements. Professional roofing contractors understand how different materials perform in specific weather conditions and can recommend systems that provide optimal protection for your particular building and budget requirements.

A comprehensive roof inspection and consultation should evaluate your current roof system's performance, identify potential vulnerabilities, and recommend material upgrades that enhance storm resistance. Learn more on our residential roofing service page for detailed information about material options and installation processes.

For commercial properties, visit our commercial roofing services section to explore membrane systems and specialized materials designed for large-scale applications in severe weather environments. Our experienced team can help you navigate manufacturer warranties, building code requirements, and long-term performance expectations to ensure your roofing investment provides maximum protection and value.

The National Severe Storms Laboratory has extensively documented the Texas Panhandle's unique position within "Hail Alley," where atmospheric conditions create some of the most destructive hailstorms in North America. These storms frequently produce hail exceeding 2 inches in diameter, making Class 4 impact resistance ratings essential for long-term roof system survival. Additionally, the region's extreme temperature swings—from sub-zero winter conditions to summer temperatures exceeding 110°F—create thermal expansion and contraction cycles that can compromise inferior roofing materials within just a few seasons.

For residential applications, impact-resistant shingles meeting ASTM standards for Class 4 hail resistance have proven most effective in this climate. Leading manufacturers like GAF have developed specialized shingle technologies that combine polymer-modified asphalt with enhanced granule adhesion systems, specifically engineered for high-impact zones. These advanced formulations maintain flexibility at temperature extremes while providing superior granule retention—critical for preserving UV protection and fire resistance over decades of exposure.

Wind uplift resistance becomes particularly crucial when considering the Texas Panhandle's frequent straight-line winds and tornadic activity. The Insurance Institute for Business & Home Safety recommends that roofing systems in this region meet or exceed ASTM D3161 Class F wind resistance standards, which test materials against sustained winds of 110 mph. Proper installation techniques, including enhanced fastening patterns and perimeter securement, can significantly improve a roof system's ability to resist wind uplift forces that commonly exceed design loads during severe weather events.

Commercial roofing systems face additional challenges due to larger surface areas and typically lower slopes that can create greater wind uplift pressures. Single-ply membrane systems from manufacturers like Carlisle SynTec have demonstrated superior performance when properly mechanically fastened and fully adhered according to FM Global wind uplift standards. The selection between TPO, EPDM, and PVC membranes often depends on specific building geometry, expected thermal cycling, and local building code requirements that may mandate higher fire ratings or puncture resistance.

Code compliance in Texas follows the International Building Code (IBC) with local amendments that often require enhanced wind resistance ratings. Property owners should verify that their roofing contractor understands these regional requirements and can provide documentation of compliance with both ICC standards and manufacturer specifications. Regular post-storm inspections and preventive maintenance become critical components of maximizing roof system lifespan in this challenging climate, with many insurance providers offering premium discounts for properties that demonstrate proactive maintenance protocols and use of impact-resistant materials.