Your roof silently battles Texas Panhandle weather extremes 365 days a year—scorching 100°F+ summers, sudden temperature swings of 40+ degrees, golf ball-sized hail, and relentless wind uplift forces. Without annual maintenance, minor issues become catastrophic failures that cost 5-10 times more to repair. Property owners who skip routine inspections often discover moisture intrusion, compromised building envelope integrity, and premature membrane deterioration only after interior damage appears—when it's too late for simple fixes.

The consequences of neglecting roof maintenance extend far beyond repair costs. Insurance companies increasingly scrutinize maintenance records during claims, and warranties can be voided without documented annual inspections. In Amarillo's harsh climate, even premium roofing systems experience accelerated aging without proactive care, turning a 20-year roof into a 12-year liability.

When Annual Roof Maintenance Requires Professional Attention

While basic gutter cleaning might seem manageable, comprehensive roof maintenance demands professional expertise to identify developing problems before they compromise your building envelope. NRCA maintenance guidelines emphasize that trained professionals can detect subtle signs of membrane degradation, fastener loosening, and thermal bridging that untrained eyes miss.

Critical maintenance tasks requiring professional attention include:

- Membrane seam inspection using specialized equipment to detect microscopic separations

- Wind uplift resistance testing to ensure fasteners maintain proper holding strength

- Thermal imaging assessment to identify moisture intrusion and insulation gaps

- Drainage system evaluation including internal drains, scuppers, and overflow provisions

- Flashing and penetration sealing around HVAC equipment, skylights, and roof-mounted systems

Texas weather conditions accelerate these deterioration processes. UV radiation breaks down elastomeric coatings, thermal cycling loosens fasteners, and hail impact creates micro-fractures that allow moisture penetration. Professional maintenance addresses these issues systematically before they cascade into major failures.

Key Decision Factors: Maintenance Investment vs. Emergency Replacement

The financial case for annual maintenance is compelling. Industry data shows that every dollar spent on preventive maintenance saves $4-7 in emergency repairs and extends roof service life by 40-60%. For a typical commercial building in Amarillo, annual maintenance costs $0.15-0.25 per square foot compared to $8-15 per square foot for emergency replacement.

Lifecycle cost analysis reveals the true value proposition:

- Maintained roofs: 18-25 year service life with predictable repair costs

- Neglected roofs: 10-15 year service life with emergency replacement expenses

- Energy efficiency preservation: Maintained roof insulation maintains optimal R-value performance

- Insurance benefits: Lower premiums and faster claims processing with maintenance documentation

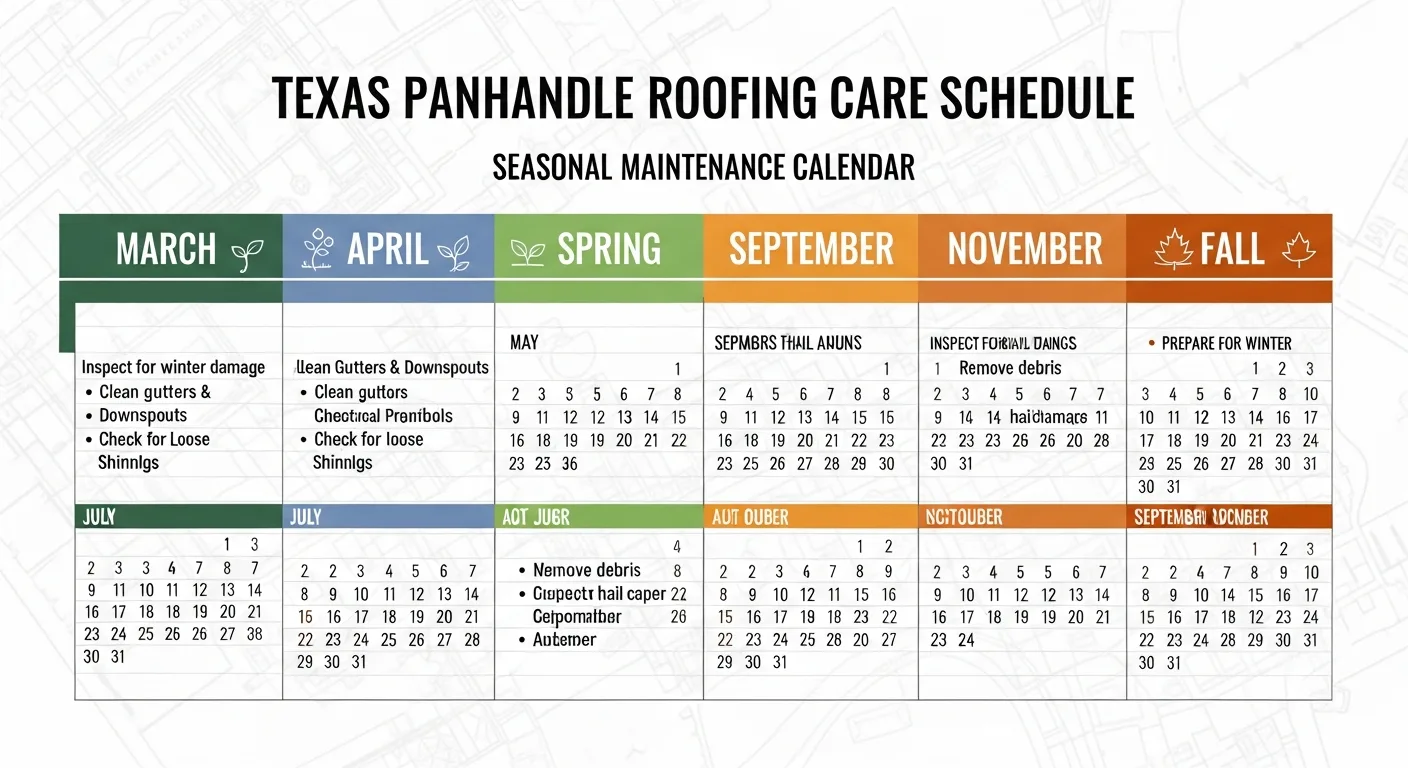

Timing considerations are crucial in the Texas Panhandle. Spring maintenance prepares your roof for summer heat stress, while fall inspections address hail damage before winter freeze-thaw cycles worsen problems. Emergency repairs during peak construction seasons cost 30-50% more due to contractor availability and material supply constraints.

Warning Signs That Indicate Immediate Professional Assessment

Certain conditions require immediate professional evaluation rather than waiting for scheduled maintenance:

- Interior water stains or moisture issues

- Visible membrane bubbling, cracking, or separation

- Ponding water persisting 48+ hours after rainfall

- Unusual energy bill increases suggesting insulation compromise

- Storm damage including hail impact or debris accumulation

Material and System Recommendations for Texas Panhandle Conditions

Effective maintenance programs must account for specific roofing system types and their vulnerabilities in extreme Texas weather. Different materials require tailored maintenance approaches to maximize performance and longevity.

Modified Bitumen Systems: Focus on seam integrity, surface granule loss, and thermal reflectivity preservation. Annual re-coating may be necessary to maintain Energy Star thermal performance standards.

Single-Ply Membrane Systems: Prioritize membrane attachment integrity, especially around perimeters where wind uplift forces concentrate. TPO and PVC systems require different cleaning protocols to prevent premature aging.

Built-Up Roofing (BUR): Monitor aggregate embedment, prevent vegetation growth, and maintain proper drainage to prevent moisture accumulation in multi-layer systems.

Metal Roofing Systems: Inspect fastener tightness, coating adhesion, and thermal expansion joint functionality. High-wind events common in the Panhandle can stress standing seam connections.

For all systems, maintaining proper thermal reflectivity is crucial. Texas heat can degrade roof surface temperatures to 160°F+, accelerating material breakdown and increasing cooling costs. Regular cleaning and recoating preserve energy efficiency benefits.

What to Expect During Professional Roof Maintenance

Comprehensive annual maintenance follows systematic protocols designed to identify and address potential problems before they require emergency intervention. Understanding this process helps property owners appreciate the value of professional service.

Phase 1: Comprehensive Inspection and Documentation

Professional technicians conduct detailed assessments using advanced tools including moisture meters, thermal imaging cameras, and core sampling equipment when necessary. This phase typically requires 2-4 hours depending on building size and complexity.

Phase 2: Immediate Repairs and Preventive Measures

Minor repairs like sealant replacement, loose fastener tightening, and debris removal are completed immediately. More significant issues are documented with repair recommendations and priority scheduling.

Phase 3: Performance Optimization

This includes drainage system cleaning, HVAC unit maintenance coordination, and energy efficiency assessments. Professional contractors often identify opportunities to improve thermal performance and reduce operational costs.

Phase 4: Documentation and Planning

Detailed maintenance reports document current conditions, completed work, and future recommendations. This documentation is invaluable for warranty compliance, insurance claims, and capital planning.

Professional maintenance typically takes 1-2 days for commercial buildings and can often be scheduled around business operations to minimize disruption. For residential properties, most maintenance can be completed in a single day.

Why Choosing the Right Contractor Matters

The quality of your maintenance program directly depends on contractor expertise and commitment to systematic care. Not all roofing contractors offer comprehensive maintenance services, and the difference in outcomes can be dramatic.

Essential contractor qualifications include:

- Manufacturer-certified technicians familiar with your specific roofing system

- Comprehensive insurance coverage including professional liability

- Documented maintenance protocols and reporting systems

- Local experience with Texas Panhandle weather challenges

- Emergency response capabilities for storm damage assessment

CRS Roofing & Construction brings over two decades of experience maintaining roofs throughout the Texas Panhandle. Our manufacturer certifications ensure maintenance work meets warranty requirements, while our local expertise addresses the unique challenges of Amarillo's climate extremes. We understand how thermal cycling affects different membrane types and how to extend roof service life in harsh conditions.

Our systematic maintenance approach combines thorough inspections with immediate minor repairs, preventing small problems from becoming major expenses. We maintain detailed records that support insurance claims and warranty compliance while helping property owners plan future capital investments.

Property owners throughout Amarillo, Canyon, Borger, and the surrounding Texas Panhandle trust our maintenance programs to protect their roofing investments. Our proactive approach has helped clients avoid emergency replacements and maintain optimal energy efficiency even in extreme weather conditions.

Don't wait for minor roof issues to become major expenses. Contact CRS Roofing & Construction today to schedule your comprehensive annual maintenance inspection. Our experienced team will assess your roof's current condition, complete necessary maintenance, and provide detailed documentation to protect your investment. Call us now or visit our commercial roofing services page to learn how our maintenance programs can extend your roof's service life and reduce long-term costs. Your roof protects everything underneath—make sure professional maintenance protects your roof.

Texas Panhandle commercial roofing systems face some of the nation's most demanding environmental conditions. NOAA weather data confirms that Amarillo experiences over 60 days annually with winds exceeding 25 mph, creating constant uplift pressures that stress membrane fasteners and edge details. During annual inspections, professionals specifically evaluate whether your roofing system maintains its NRCA-recommended wind uplift ratings through systematic fastener pattern checks and perimeter securement assessments.

The thermal cycling experienced in the Texas Panhandle—where rooftop temperatures can swing from 120°F in summer to below freezing within 24 hours—places extraordinary stress on commercial membrane systems. TPO and EPDM membranes from manufacturers like Carlisle SynTec require annual evaluations of seam integrity, as thermal expansion and contraction can compromise heat-welded joints over time. Professional maintenance teams use specialized equipment to test seam strength and identify areas where membrane movement has created stress concentrations.

Hail damage assessment requires particular expertise in the Texas Panhandle, where National Severe Storms Laboratory research shows golf ball-sized hail occurs with above-average frequency. Impact damage isn't always immediately visible—membrane bruising and granule loss on modified bitumen systems can compromise weatherproofing months before leaks appear. Annual inspections must include detailed documentation of any impact marks, as insurance claim requirements increasingly demand photographic evidence linking storm events to specific damage patterns.

Commercial building owners should understand that International Building Code compliance requires proper maintenance to maintain structural integrity ratings. Failed maintenance can void manufacturer warranties and create liability issues during wind or hail damage claims. Professional maintenance programs include thermal imaging to detect moisture intrusion, core sampling to assess insulation condition, and systematic documentation that satisfies both warranty requirements and insurance underwriting standards.